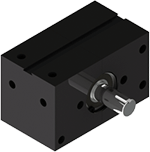

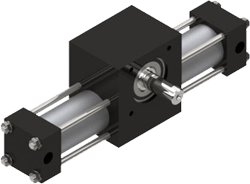

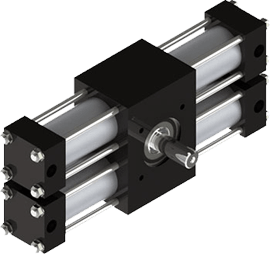

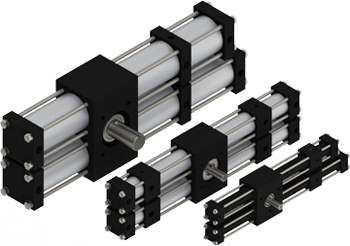

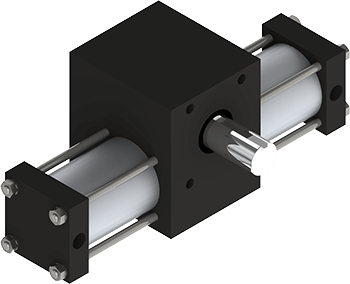

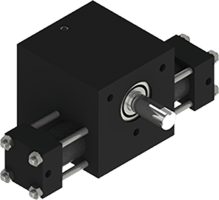

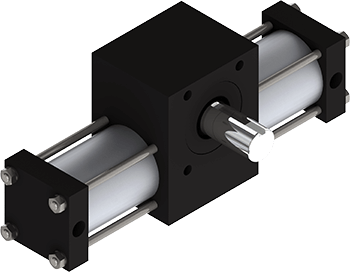

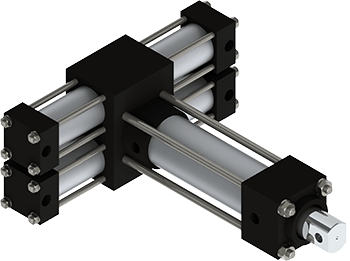

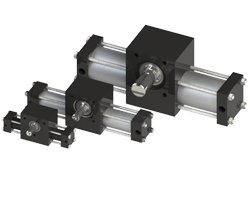

Compact Rotary Actuators

Compact Rotary Actuators

Rotomation's compact rotary actuators are designed for applications where high torque in a small space is important. Their unitized construction minimizes space requirement and provides a clean appearance. All common options are available, and some also have cushions, washdown protection, and metric shafts sizes available. Standard and special rotations up to 190 degrees are available. A032 and A752 are dual rack actuators, eliminating lash (free rotary play of the shaft) at the end of rotation.

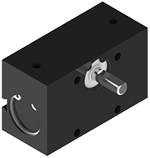

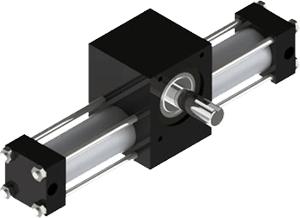

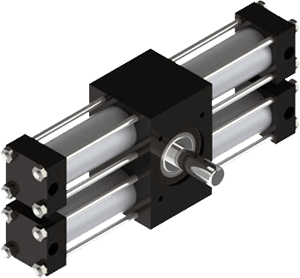

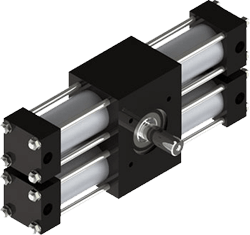

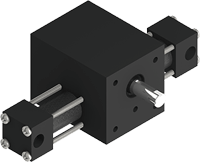

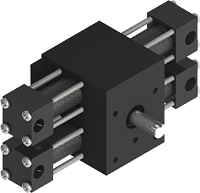

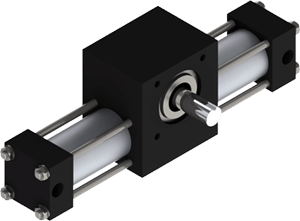

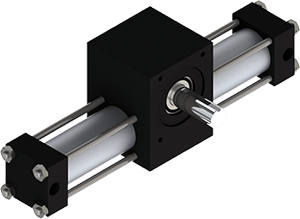

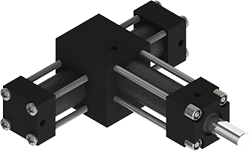

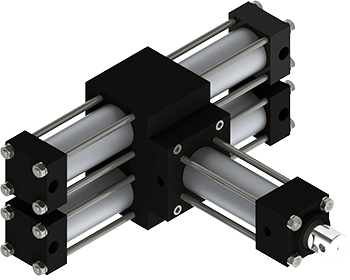

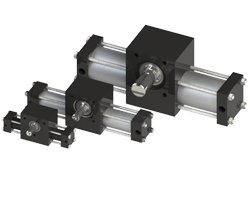

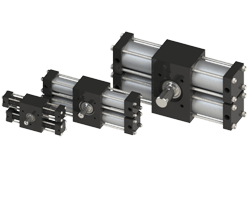

Single Rack Tie Rod Rotary Actuators

Single Rack Tie Rod Rotary Actuators

Tie rod construction offers maximum configurability and durability, and are fully rebuildable. Single rack actuators are designed for general applications where reliability and durability are important and where a small amount of lash (free rotary play of the shaft) is tolerable. All common options are available and also hollow shafts, integrated cushions or flow controls, washdown protection, high temperature or hydraulic seals, high-cycle construction. Fifteen standard rotations, from 30 to 730°, and special rotations available up to 1,080°.

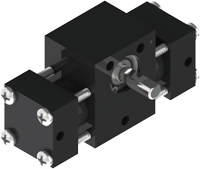

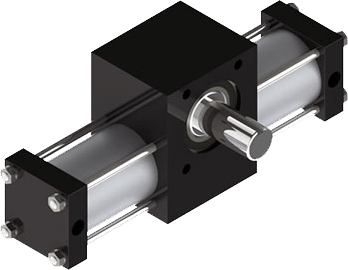

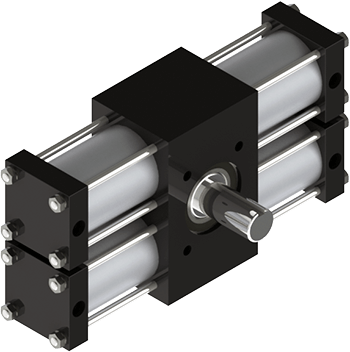

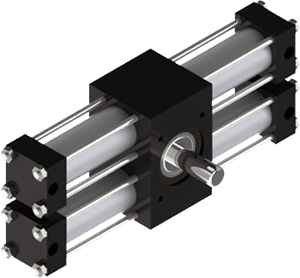

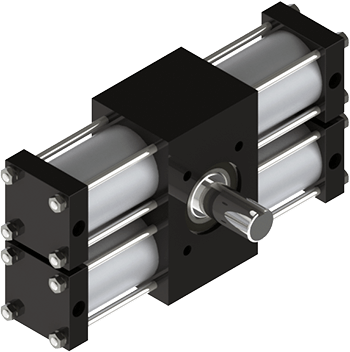

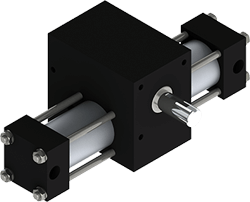

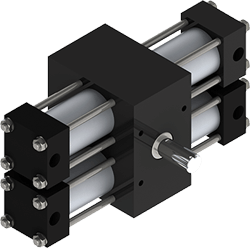

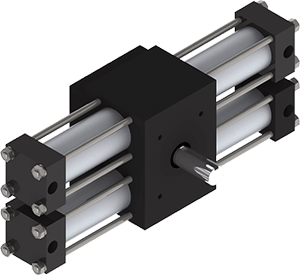

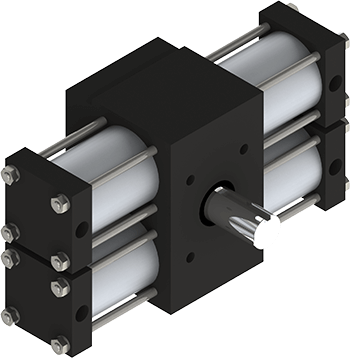

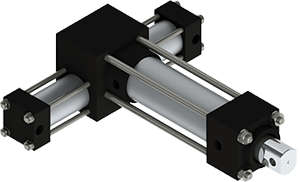

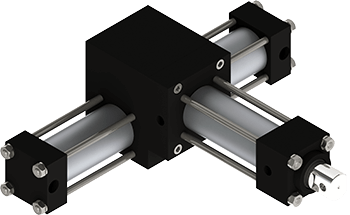

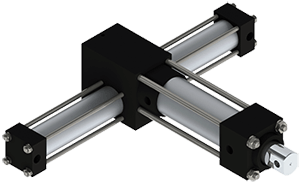

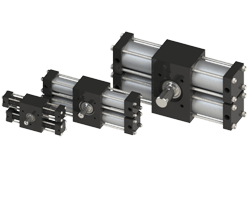

Dual Rack Tie Rod Rotary Actuators

Dual Rack Tie Rod Rotary Actuators

Dual rack actuators have the additional advantages of double torque and zero lash at the ends of the rotation without increasing the footprint of the actuator. All construction features and options available on single rack tie rod actuators are also available on dual rack actuators.

![]()