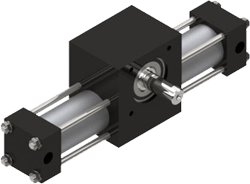

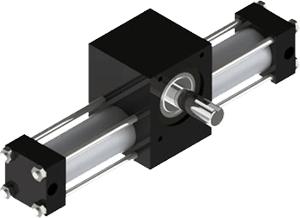

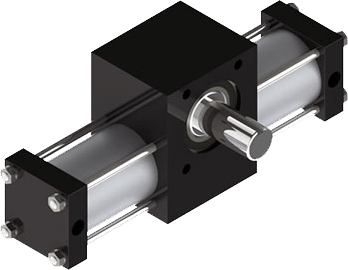

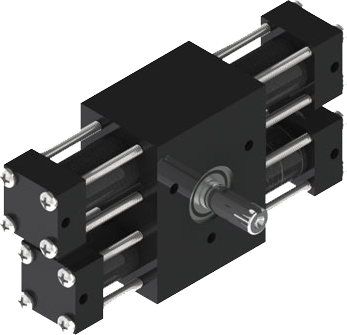

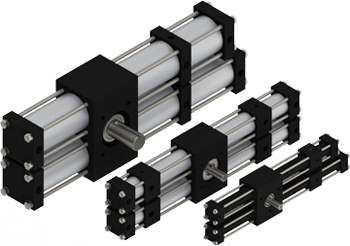

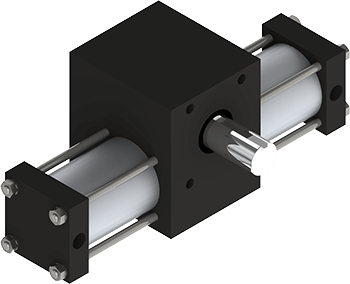

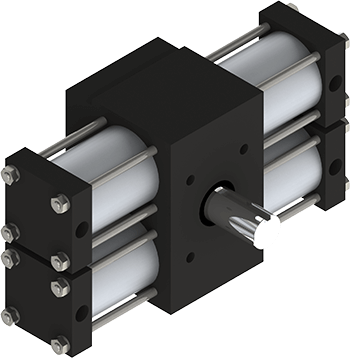

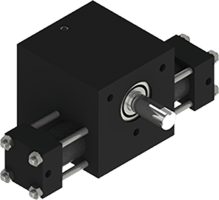

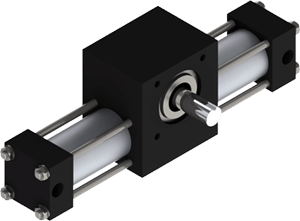

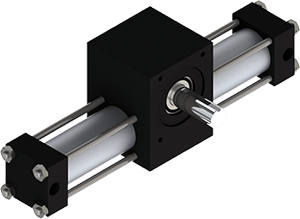

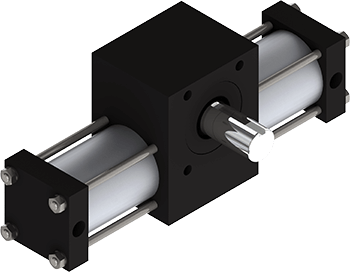

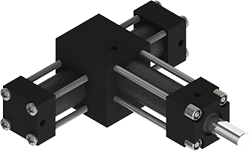

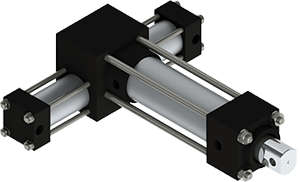

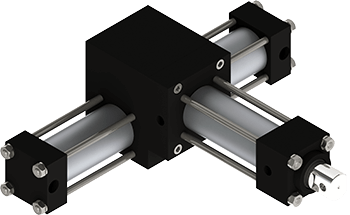

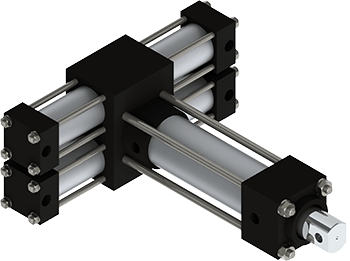

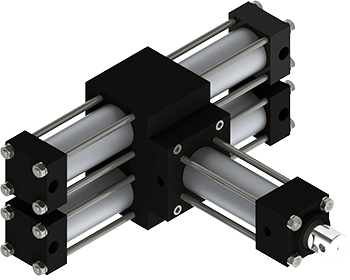

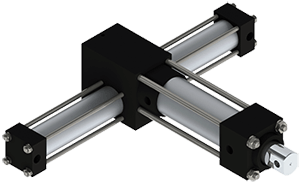

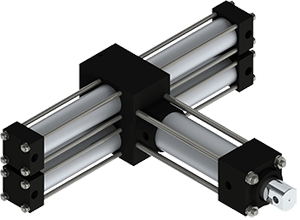

Pick & Place Actuators

![]()

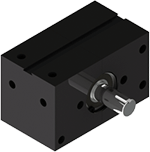

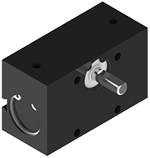

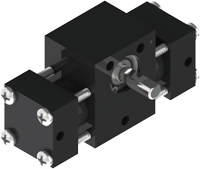

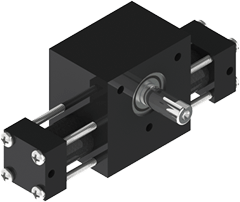

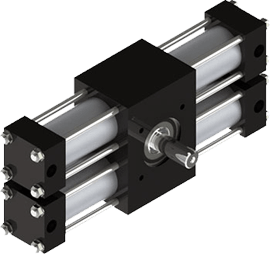

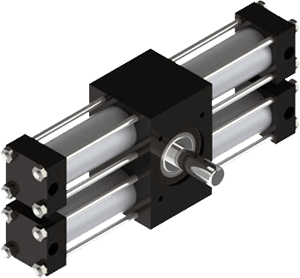

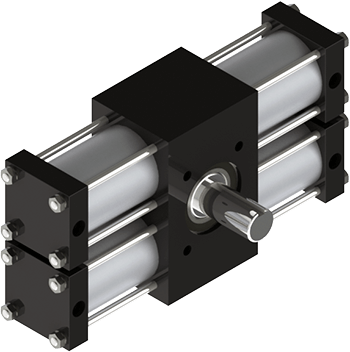

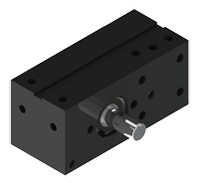

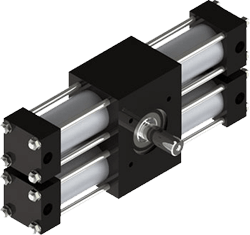

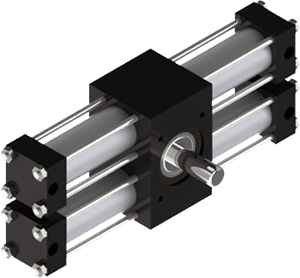

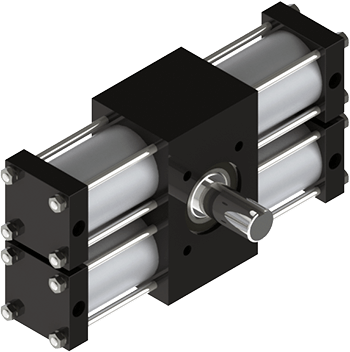

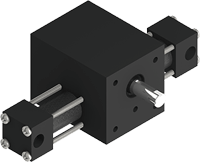

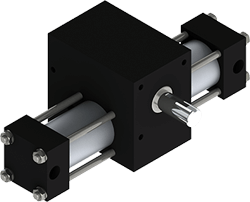

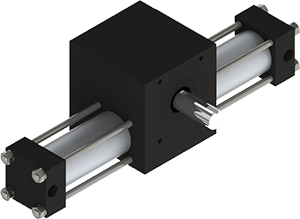

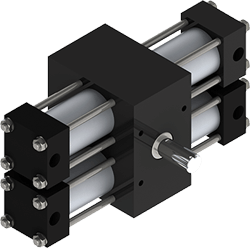

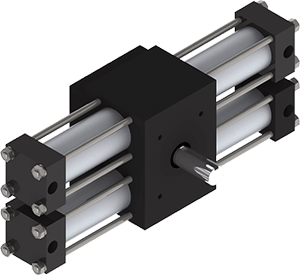

Basic pick & place actuators combine a rotary section with a linear cylinder to provide independently-controlled linear and rotary motion. These actuators are also known as multi-motion actuators, and even though their rotary sections provide rotary motion, they can also provide stepping motion in certain sizes (contact us for more information). All Rotomation pick & place actuators feature black-anodized aluminum bodies, stressproof steel rods, ball bearings, and stainless steel hardware.

Common Options: two rod types, 1 or 2" long stop tube on linear section, auxiliary shaft, adjustable rotation, bumpers, integrated flow control or cushion needle valve, high-temperature seals, mount plates, magnetic switches for position feedback, and various port locations.

Standard rod strokes: from 0.50" to 12.00", in 0.25" increments.