ROTARY

ROTARY

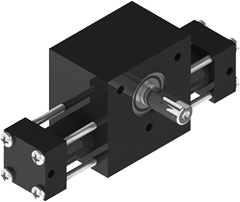

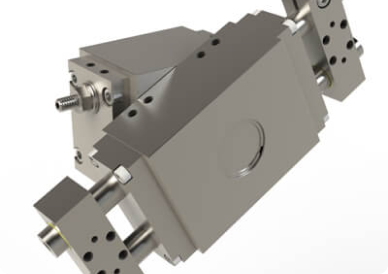

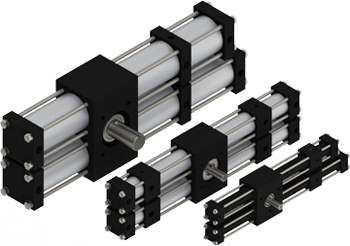

Rotary Actuators

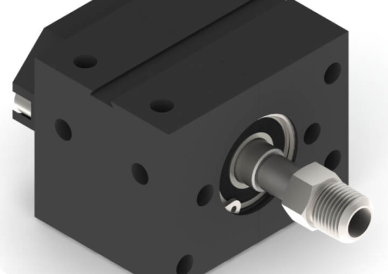

Compact

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

Diameter

*80psi

Torque: 7-14 in-lb*

Shaft: 1/4"

Diameter

*80 psi

Torque: 35 in-lb*

Shaft: 3/8"

Diameter

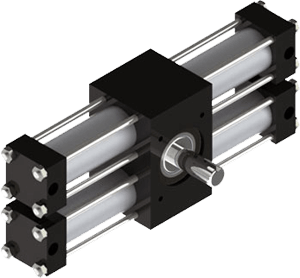

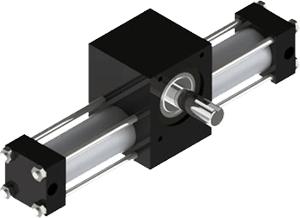

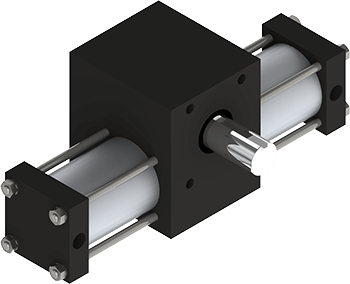

*80 psiSingle Rack Tie-Rod

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

Diameter

*80psi

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

Diameter

*80 psi

Torque: 39 in-lb*

Shaft: 1/2"

Diameter

*80 psi

Torque: 119 in-lb*

Shaft: 3/4"

Diameter

*80 psi

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

Diameter

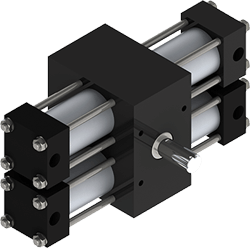

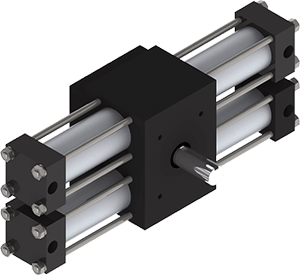

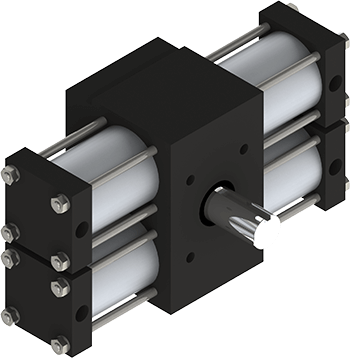

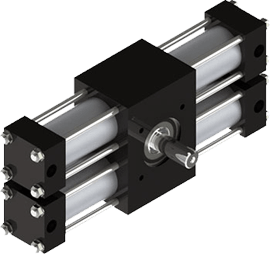

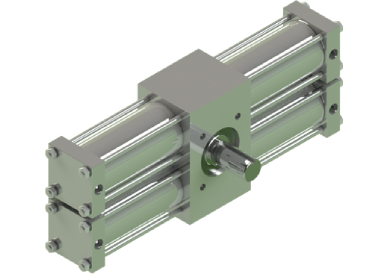

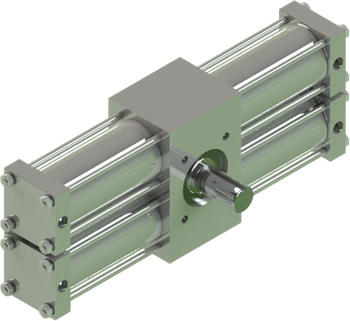

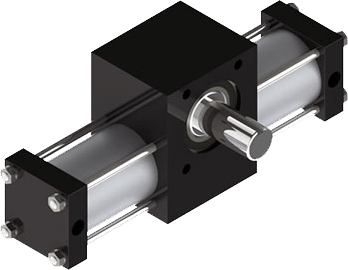

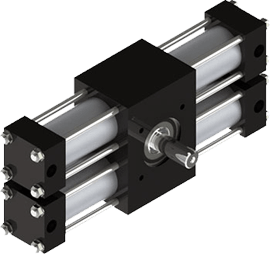

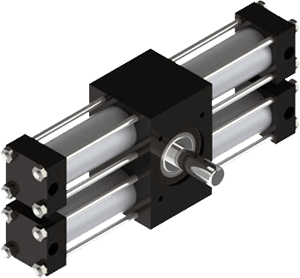

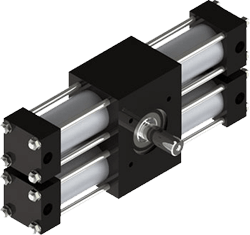

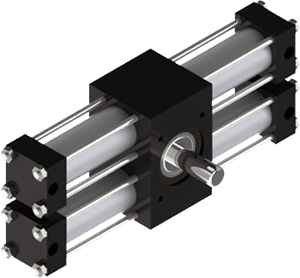

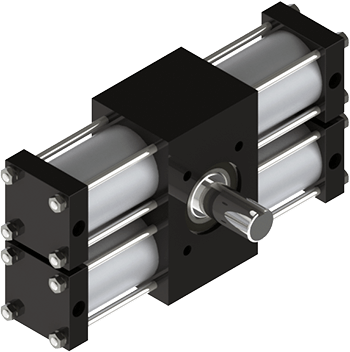

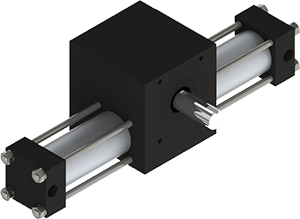

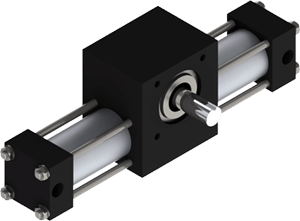

*80 psiDual Rack Tie-Rod

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

Diameter

*80psi

Torque: 78 in-lb*

Shaft: 1/2"

Diameter

*80 psi

Torque: 238 in-lb*

Shaft: 3/4"

Diameter

*80 psi

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter

*80 psi

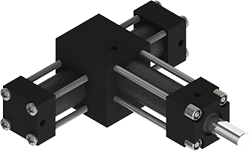

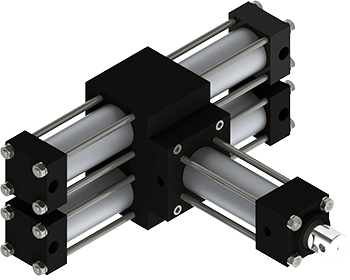

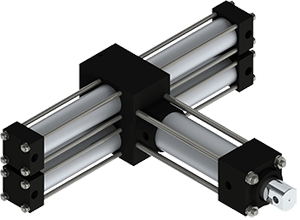

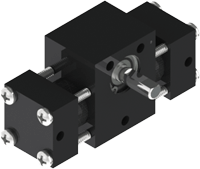

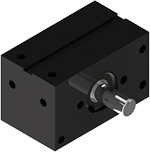

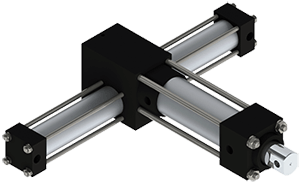

MULTI-POSITION

MULTI-POSITION

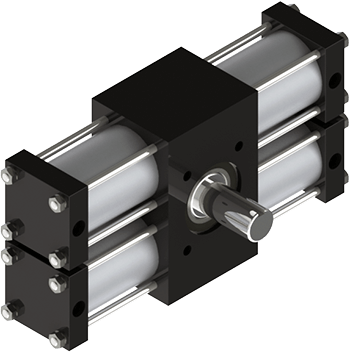

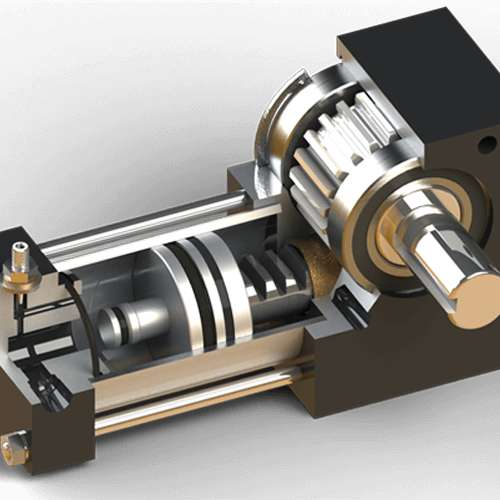

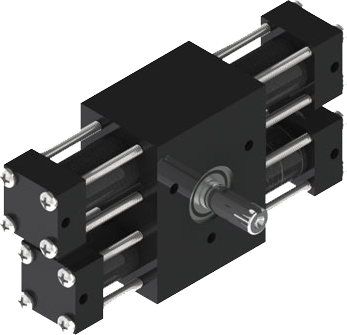

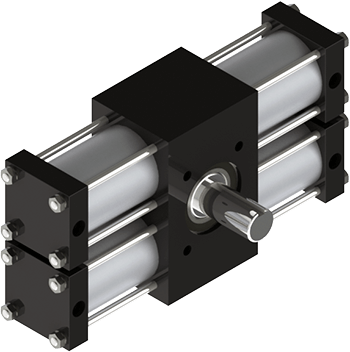

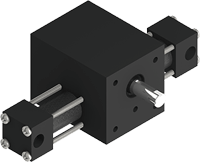

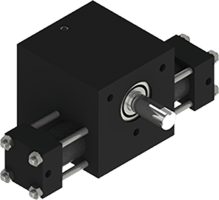

Multi Position

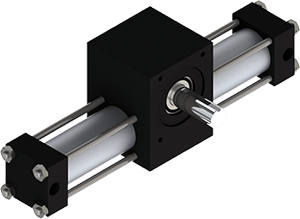

Three Position Actuators

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

Diameter

*80psi

Torque: 12 in-lb

Shaft: 3/8"

Diameter

*80 psi

Torque: 39 in-lb*

Shaft: 1/2"

Diameter

*80 psi

Torque: 119 in-lb*

Shaft: 3/4"

Diameter

*80 psi

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

Diameter

*80 psi4 or 5 Position Actuators

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter

*80psi

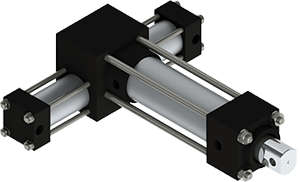

INDEXING

INDEXING

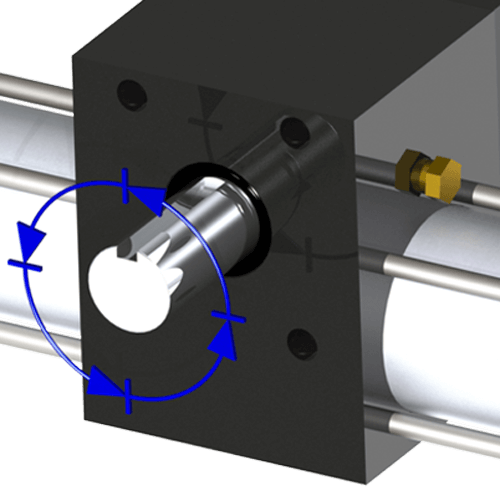

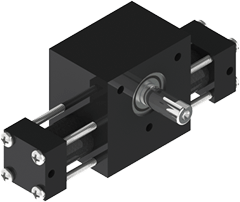

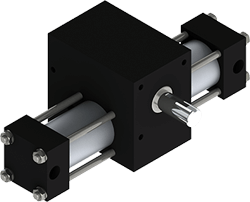

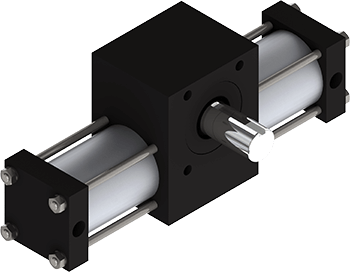

Indexing Actuators

Single Rack

Torque: 9 in-lb*

Shaft: 3/8*

Diameter

*60psi

Torque: 29 in-lb*

Shaft: 1/2"

Diameter

*60psi

Torque: 89 in-lb*

Shaft: 3/4"

Diameter

*60psi

Torque: 208 in-lb*

Shaft: 1"

Diameter

*60psi

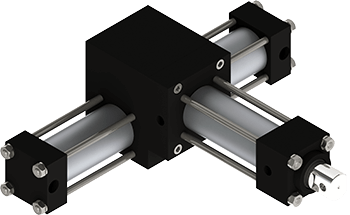

STEPPING

STEPPING

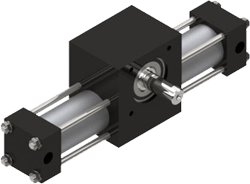

Stepping Actuators

Single Rack

Torque: 12 in-lb*

Shaft: 3/8"

Diameter

*80psi

Torque: 39 in-lb*

Shaft: 1/2"

Diameter

*80psi

Torque: 119 in-lb*

Shaft: 3/4"

Diameter

*80psi

Torque: 277 in-lb*

Shaft: 1"

Diameter

*80psi

P & P

P & P

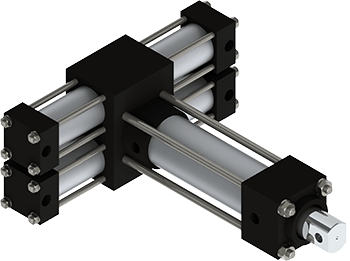

NITPICKER

NITPICKER

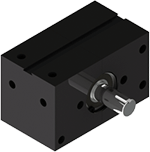

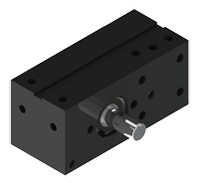

Nitpicker Actuators

Single Rack

Torque: 39 in-lb*

Shaft: 1"

Diameter

*80psi

SMA

SMA