Product Line

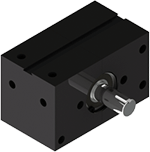

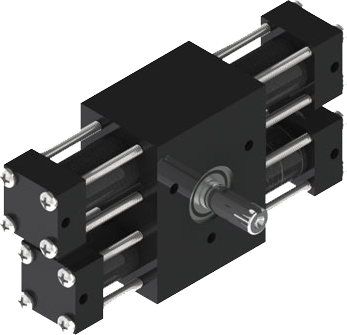

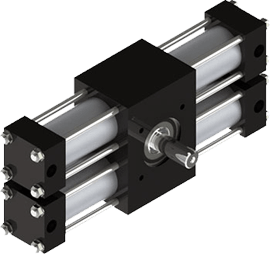

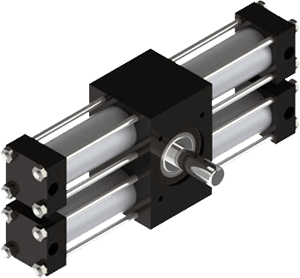

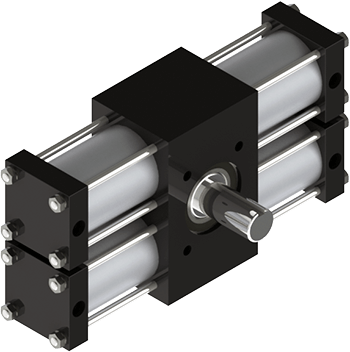

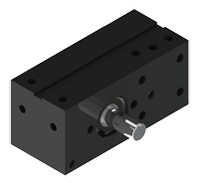

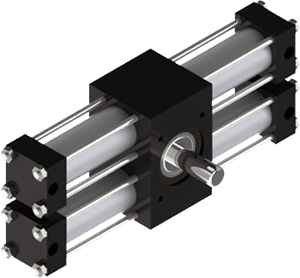

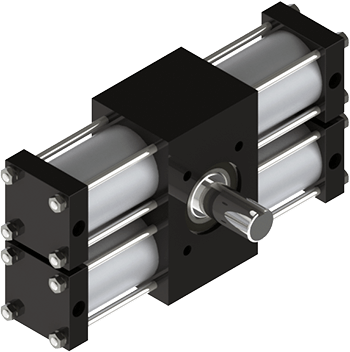

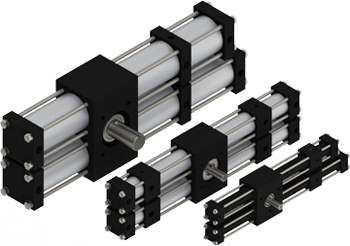

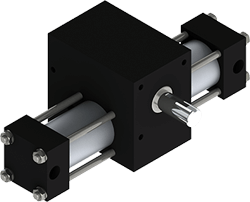

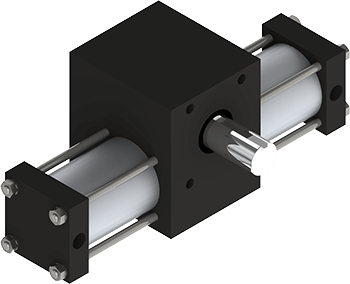

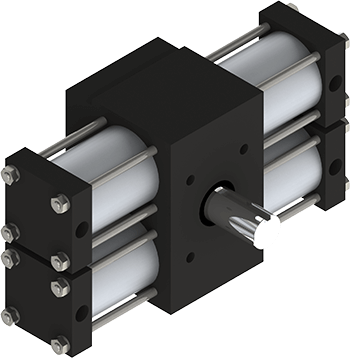

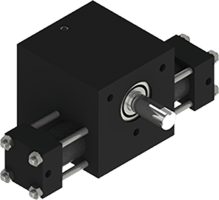

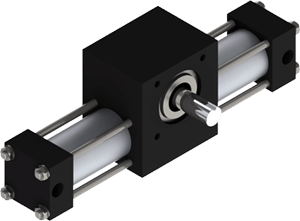

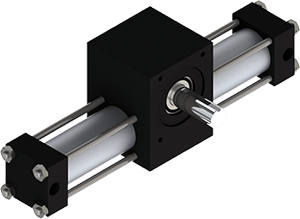

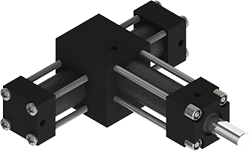

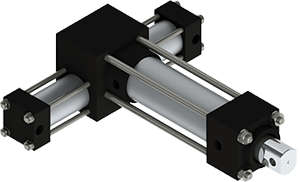

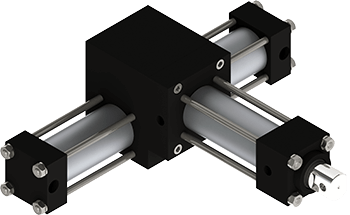

The Rotomation product line includes pneumatic and low pressure hydraulic actuators operating at typical pressures of 80 and 250 psi, respectively. All of our actuators, except for the AL75, provide rotary motions generated by a rack and pinion mechanism, in which a piston pushes one of the ends of a gear rack, turning the meshed pinion gear back and forth, depending on which piston is pressurized at the moment.

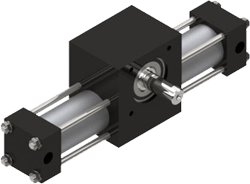

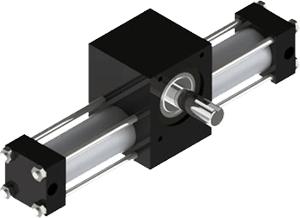

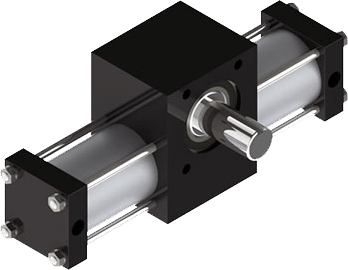

Our rotary actuators have a one-piece pinion shaft so that back and forth torque is directly transferred to the shaft.

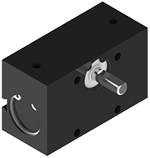

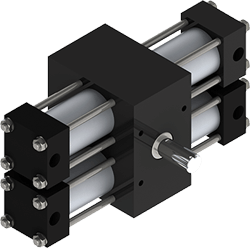

Our stepping actuators deliver torque in a single direction in steps by connecting the pinion to the shaft with a one-way clutch.

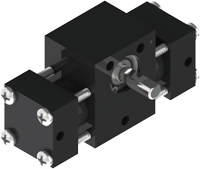

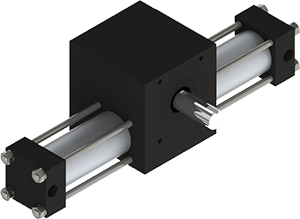

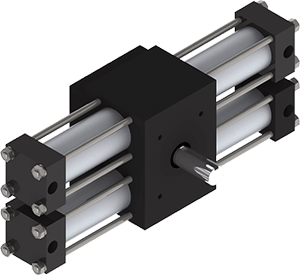

With a similar drive mechanism but with precise stopping capability, our indexing actuators produce accurate angular steps using a ratchet and pawl mechanism that provide the solid stop on its shaft.

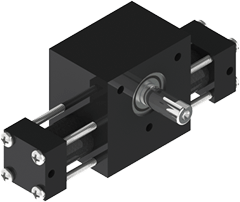

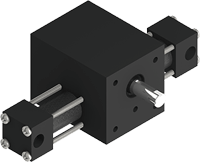

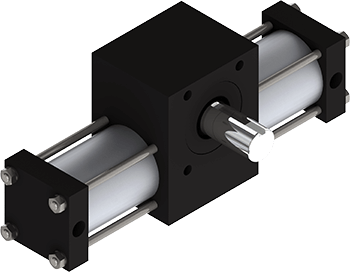

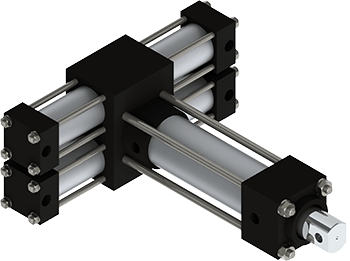

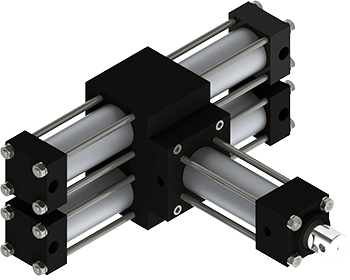

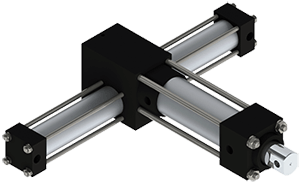

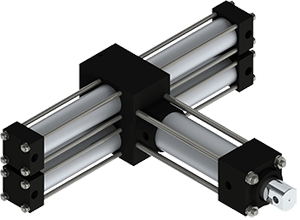

Pick and place actuators combine rotary motions and linear motions by transmitting rotary torque to a rod in its linear cylinder via a shaft-spline connection.