-

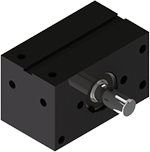

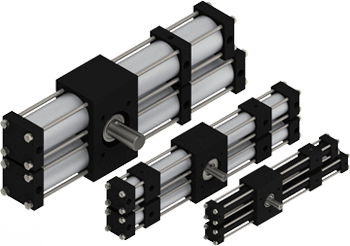

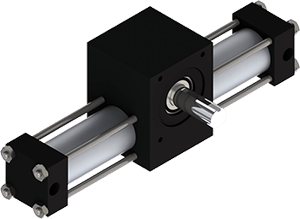

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

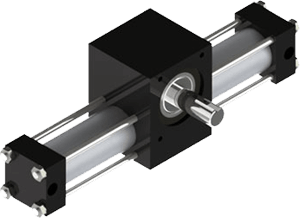

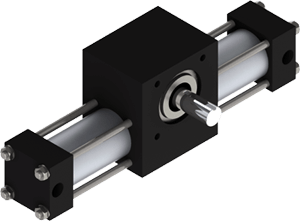

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

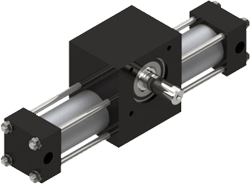

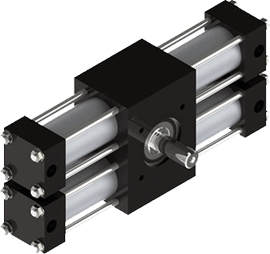

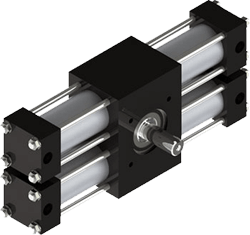

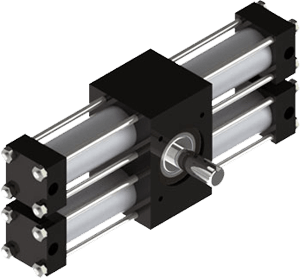

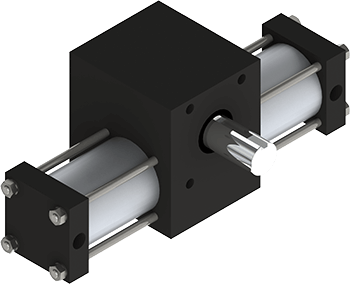

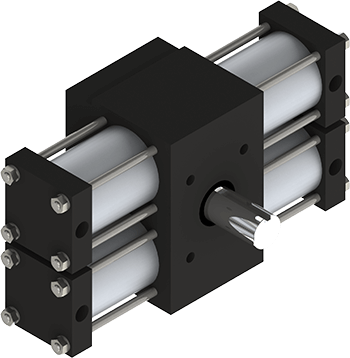

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

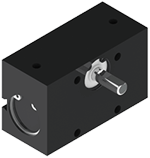

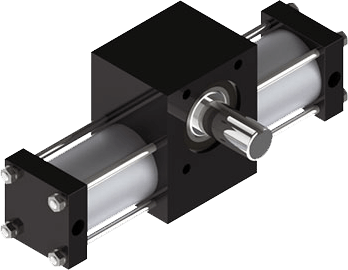

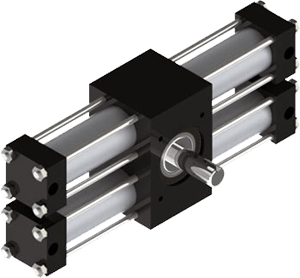

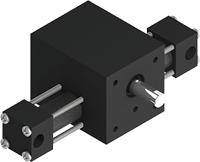

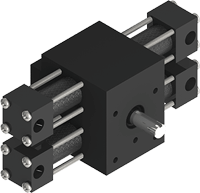

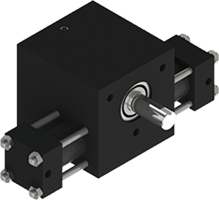

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

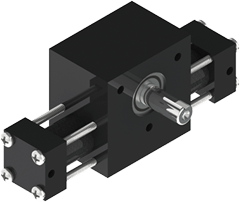

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

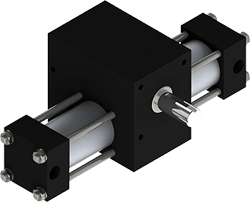

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

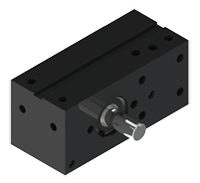

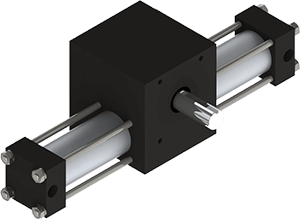

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

Whitepaper: What Are Multi-Position Actuators and Where Do They Excel

Executive Summary:

With the advancement of technology in industrial automation, multi-position actuators have become an integral part of modern machinery. These devices can hold multiple positions during their operation, unlike the more common two-position actuators. This white paper explores the concept of multi-position actuators, their advantages, working principles, and the various applications where they excel.

Introduction:

Multi-position actuators are devices designed to accurately move and control mechanisms through multiple stops, positions, or states predefined by mechanical components. This contrasts with servo- or stepper-based actuators with essentially infinite positioning capability. Their capability to halt and hold at pre-defined positions makes them useful for providing more complex movements in various industrial processes while maintaining the simplicity of on-off control devices. Servo or stepper systems require motion control hardware and software, drivers, and in many cases, feedback devices.

Definition and Working Principle:

Multi-position actuators operate using pneumatic or hydraulic power. They convert this energy into mechanical motion, to move machine components to specific locations based on input signals.

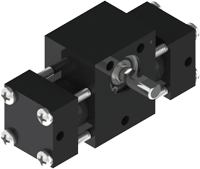

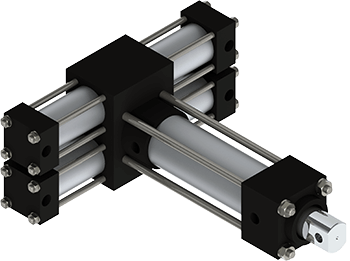

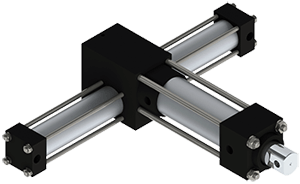

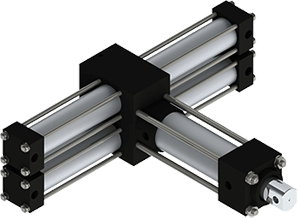

Three-Position Actuators:

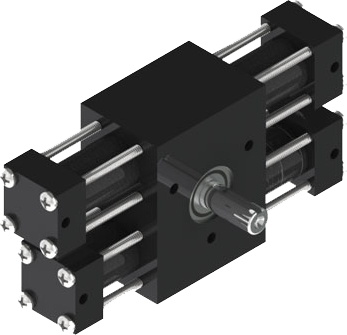

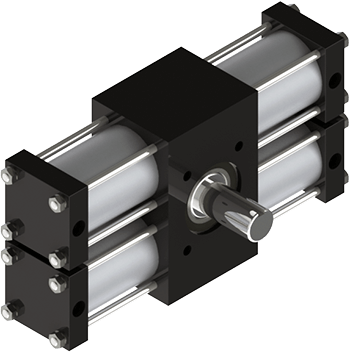

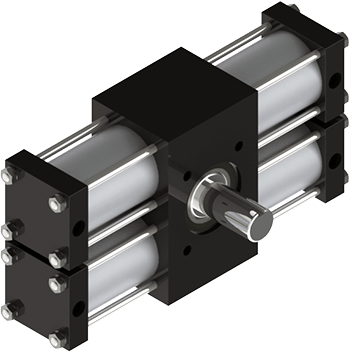

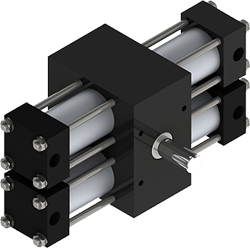

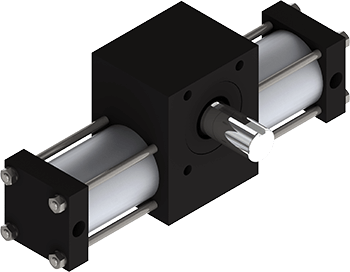

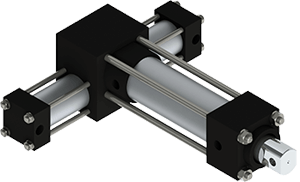

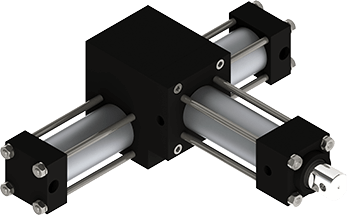

Fluid power multi-position actuators are based on standard two-position actuators, with the addition of internal stops and/or auxiliary cylinders. The most common configuration is a three-position actuator, which is offered by many actuator manufacturers. For actuators with floating pistons, this can be accomplished by installing stop tubes into two of the cylinders of a dual rack actuator.

For actuators with captive pistons (attached to or integral to the racks), auxiliary cylinders are employed:

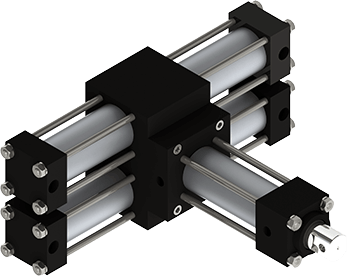

Four and Five-Position Actuators:

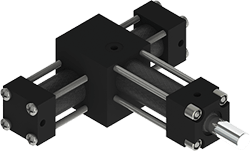

Actuators with floating pistons can be configured to provide up to five positions. In addition to the stop tubes for three positions, auxiliary cylinders are added in pairs for each additional position. These are single-acting air cylinders with rods projecting through bearings mounted in the actuator end caps. Each pair is made to capture the pistons and racks in a position intermediate between the other positions.

Lash In Multi-Position Rotary Actuators:

Rack and pinon rotary actuators must have a small amount of clearance (lash) between the teeth of the rack and those of the pinion in order to avoid binding and excessive wear. This lash shows up as free play of the output shaft and can vary from a fraction of a degree up to several degrees. There are means of avoiding this using anti-lash mechanisms, but those add wear and friction.

Dual rack actuators usually have extra stroke built into two cylinders, effectively eliminating the lash at the ends of stroke. For multi-position actuators, the lash at the intermediate positions can be greatly reduced or eliminated by careful layout of the features and compensation for tolerance buildup.

If both stop tubes are located on the same rack, opposite each other, then the lash at the mid position will be the same as a single rack version of the actuator. But if the stop tubes are located on the same side of the actuator, the lash can be eliminated.

Similarly, if the auxiliary cylinders are mounted opposite each other so that they capture a single rack, then the mid location will have the same lash as a single rack actuator.

In both cases, tolerance buildup of several parts in the assembly must be eliminated to achieve near-zero lash. This can be done using shims installed in appropriate locations. This is an extra step in the assembly process but results in a more precise actuator.

Controls for Multi-Position Rotary Actuators:

A two-position rotary actuator is usually driven by a four-way directional control valve. For multiple positions, an additional 3-way directional control valve is added for each additional position. An additional flow control valve or pair of valves may be needed for optimum control of the actuator, depending on the inertia and orientation of the load.

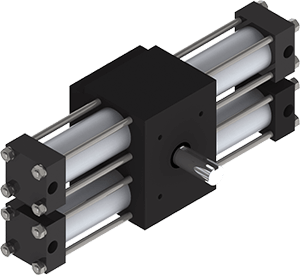

Advantages:

Multi-position rotary actuators are powerful, rugged components that have several advantages when compared with other solutions. Compared to electric servo or stepper-driven actuators, they are less expensive, much simpler to implement, and can operate in harsh or explosive environments. Compared to combinations of multiple two-position actuators, they are much more compact, simple to design, and do not require additional hardware to be designed and added to the assembly.

Applications Where Multi-Position Actuators Excel:

Positioning: Moving a component to multiple orientations to present different faces of the part to robots, welding or assembly operators, or inspection tools is a perfect application for multi-position actuators

Sorting: Three position actuators are the most chosen for this application where they are directing parts into different channels depending on orientation, defect determination, or type. But there are cases where four or five-position actuators would be called for.

Valve Actuation: Especially in the process industries, multi-position valves are often used to simplify plumbing and control. Using a multi-position rotary actuator is a simple, compact, and effective solution.

Multiple Process Transport: A multi-position actuator can simplify the task of moving a part to multiple processing stations. A single engagement/disengagement of the part reduces positioning errors and required components.

Conclusion:

Multi-position fluid power rotary actuators are rugged, precise components that give the machine or tool designer great flexibility to position parts and components into various positions using one component with a single rotary axis. This can greatly simplify the design and build process, reducing cost, space requirements, and parts count. The resulting simplification also reduces setup and maintenance costs.

In addition, these actuators are well suited to operation in harsh environments where electrical solutions may be difficult or impossible to implement.

Call to Action:

Organizations seeking to improve precision, efficiency, and versatility in their operations should consider the integration of multi-position rotary actuators. They offer an off-the-shelf solution to positioning problems that otherwise could require substantial design effort and add to the complexity and cost of automated equipment.