Product Line

-

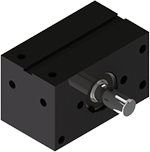

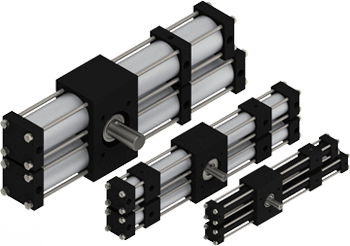

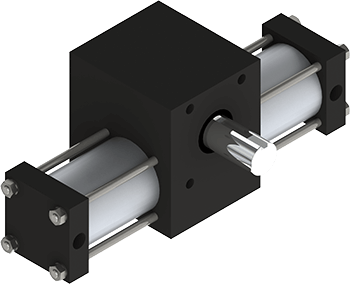

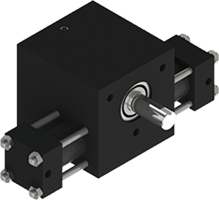

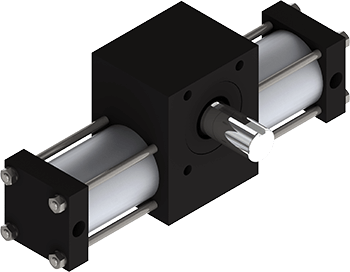

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

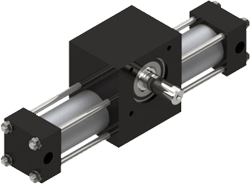

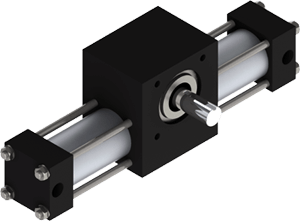

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

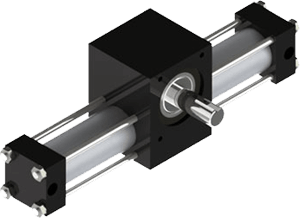

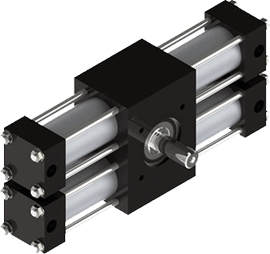

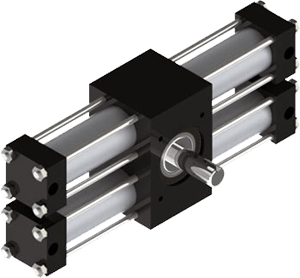

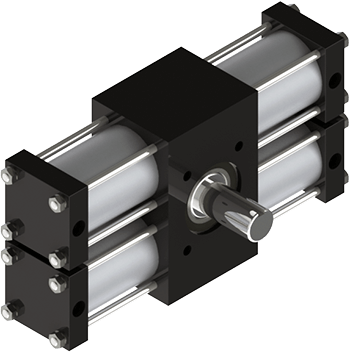

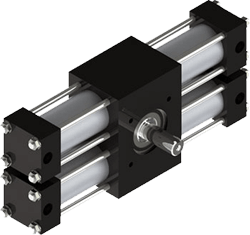

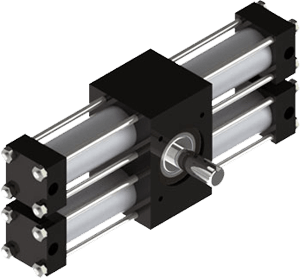

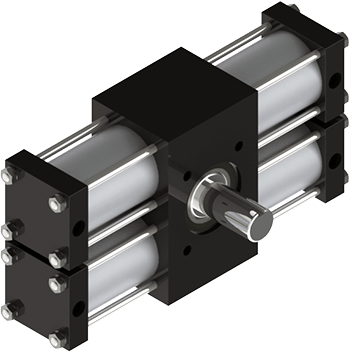

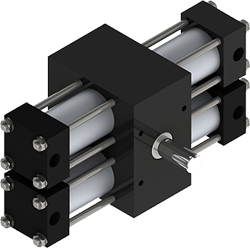

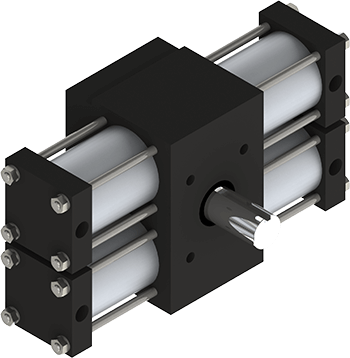

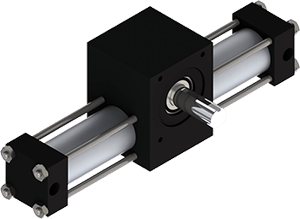

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

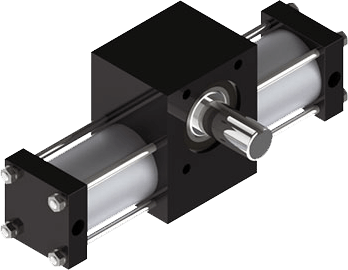

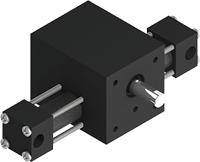

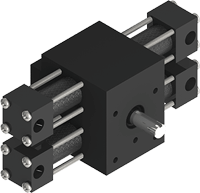

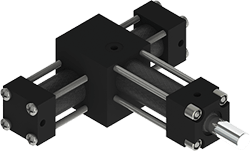

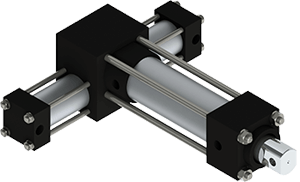

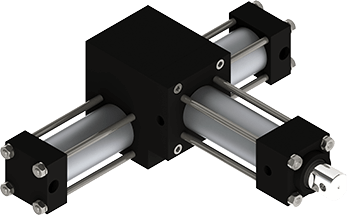

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

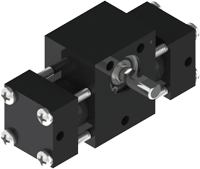

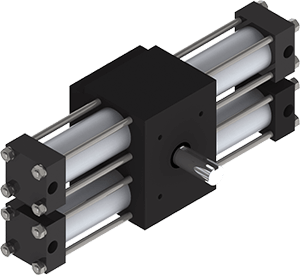

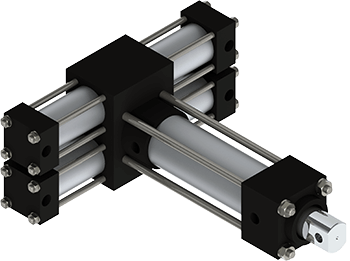

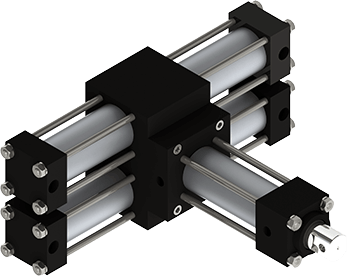

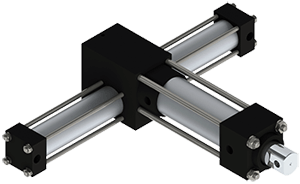

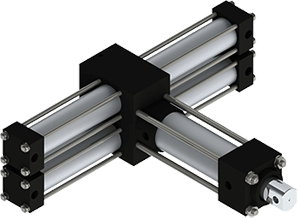

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

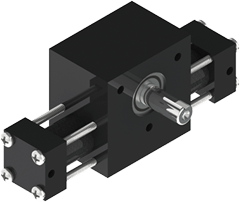

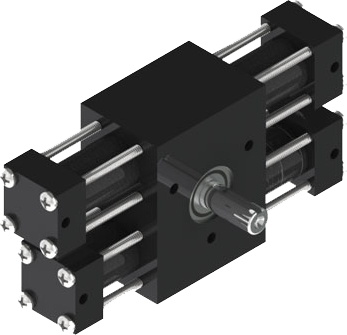

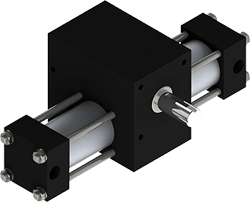

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

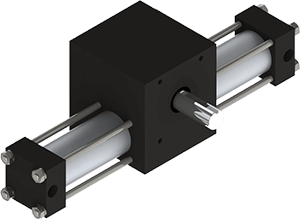

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

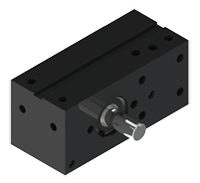

Shaft Mounting Adapters

Shaft Mounting Adapters

Every Day is Earth Day at Rotomation

Rotomation firmly believes in environmental responsibility. By practicing corporate sustainability, we create business value by incorporating green values into our operations. We look to bring about positive changes for the environment, from our internal operations to our customers and business partners.

Our ongoing practices:

- Work with eco-friendly suppliers as much as possible

- Practice thorough recycling programs within the company

- Reduce paper trails by sending documents electronically

- Build partnerships with other eco-friendly companies and organizations

Our initiatives:

- Solar power – our 35 Kilowatt Solar Photovoltaic Array provides over half of our energy needs

- Reuse and Recycle – we:

- Reuse packaging materials as much as possible

- Recycle all scrap metal and materials, paper, and unusable packaging

- Recycle computer equipment in partnership with a local technology company

- Recycle all paper and plastic cafeteria goods

- Recycle shop fluids with one of the founding partners of NASCAR Green

- Drinking Water – we use filtered water, replacing water bottles

- Paperless – we:

- Handle all billing and payables electronically whenever possible

- Reduced subscriptions to printed materials

- No longer use faxing

- Grounds – our property area contains native vegetation as it was before clearing; we do no watering, fertilizing, weed control, or use pesticides, ensuring clean runoff

We are continually looking for ways to practice environmental sustainability. Let us know of initiatives you have taken to protect our planet!

Contact Us