-

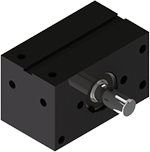

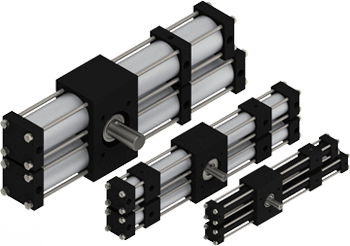

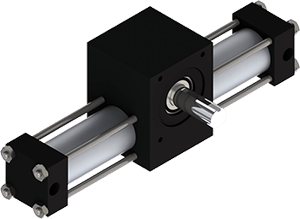

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

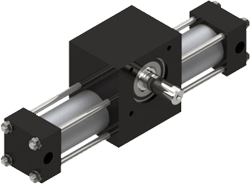

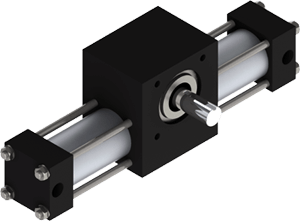

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

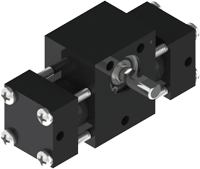

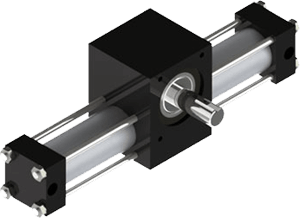

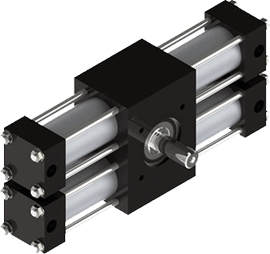

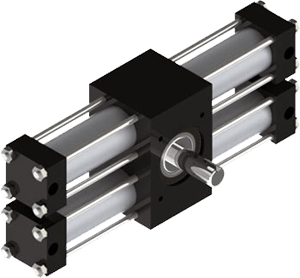

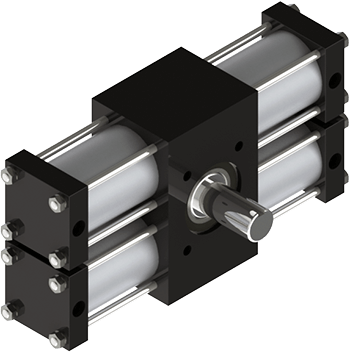

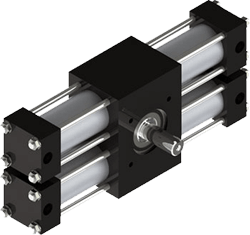

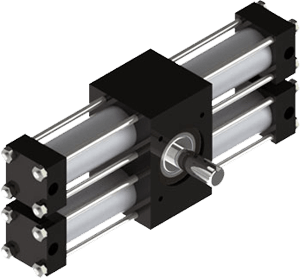

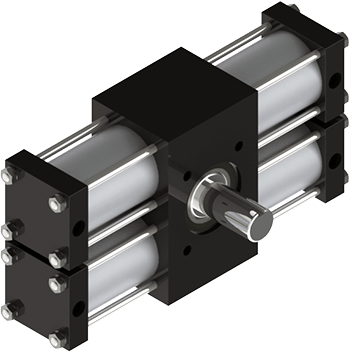

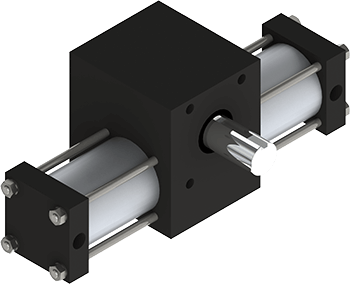

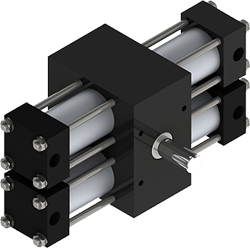

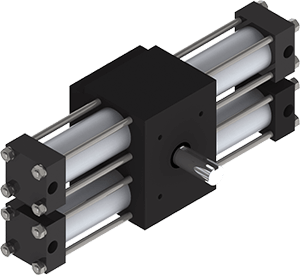

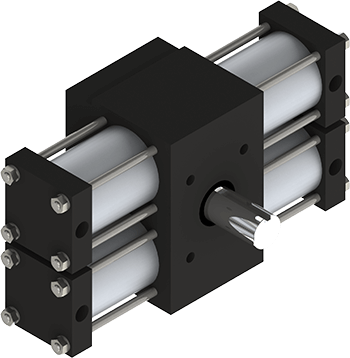

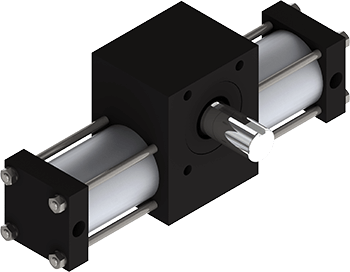

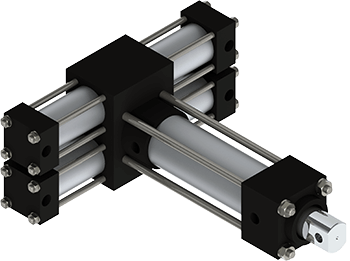

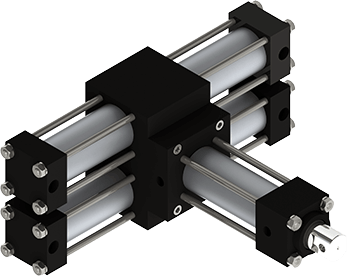

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

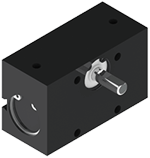

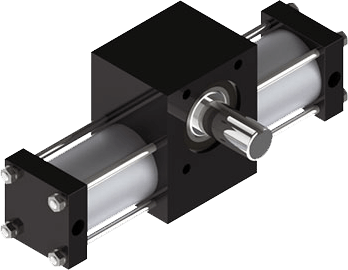

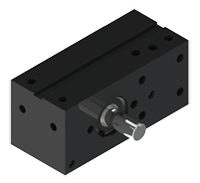

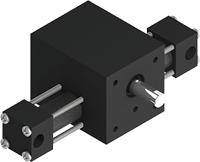

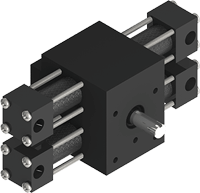

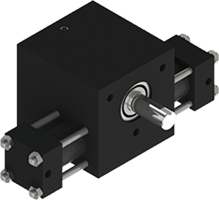

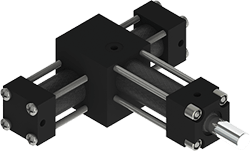

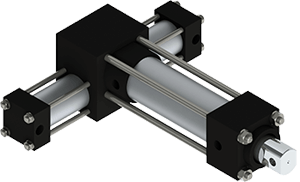

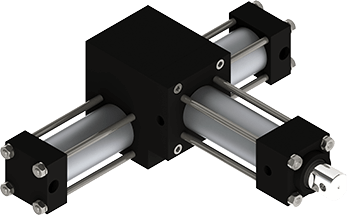

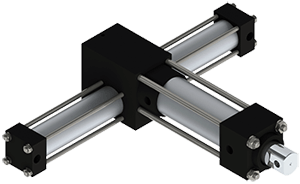

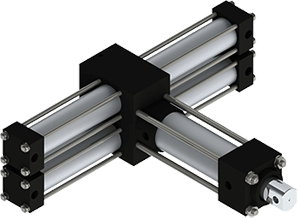

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

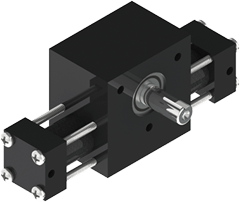

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

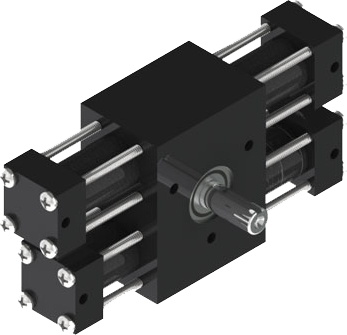

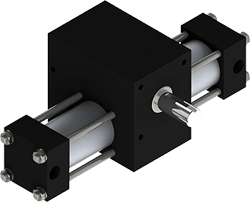

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

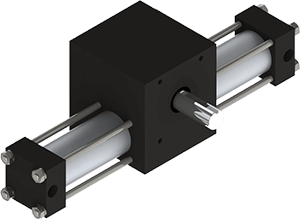

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

Testimonials

Unpublished

Holy cow! these people are rockstars! I have a Rotomation on our canning line. So the canning manufacturer was the one who actually bought the equipment from Rotomation but about a million cans and four years later I’m well out of any warranties. Anyway, it started off I needed just a small part for repair on the Rotomation. They overnighted it at no charge!

Then human error set in. I know I miss assembled something and could not figure it out. Hours and hours of tech support on the phone and were extremely patient, did a Team meeting for a few minutes, exchanged photographs and diagrams. All in all, it was several hours of tech support throughout the day today. Finally, they help me figure out my human error and everything is working at should be they really went above and beyond the call and I would have to say I highly would recommend them and their equipment to anybody based on my experience!!! Bob Southard, Burnt Hickory Brewery 7/15/21

Dear Mr. Lane,

It is with great pleasure that I tell you, on behalf of the whole Nammo Space team, that the launch of our first hybrid sounding rocket was a complete success.

As part of the Ground Support Equipment for this launch (as well as during the static test campaign), the 3 positions actuators that we acquired from you were used to fill the propellant in the rocket and to pressurize the full system. Both actuators worked perfectly fine and we are very happy with their behaviour. You can find attached a picture of the installation of the A32 actuator on the launch pad with the rocket already in position.

Bastien Haemmerli

Development Engineer – Hybrid Rocket Propulsion

Aerospace Propulsion

Nammo Raufoss AS

Norman, I pass by this indexer often. It is a X3-120-CW-S75-3F1-3C-E that you sold me in 2005. It just keeps plugging away.

Roger Brown

Norman, no one gives an outstanding quality of technical support which you do. It is my opinion that is the reason for our getting orders and why you can get as much business as you want. To even get commercial responses from most firms is difficult but technical ones on the level you offer simply do not exist. Many thanks!

Kindest regards,

Richard

“I wanted to thank you for the extra mile effort you put into meeting our needs on this project. In two days you assembled all of the actuators we needed. Your competitor took 2+ days to give us a quote and they did not even offer us a workable solution. I have known of your product line for many years, but now I know about your customer service. Thank you again.”

James Brodhead

Boeing Commercial Airplane Co.

“Jenna – Can I just say, it has been a while since I have worked with someone with such great customer service. Thank you very much for all of your help!”

Audrey Lartey

“What a gift to the students (of Spruce Creek High School) to be able to work side by side with an experienced engineer to build their competition robots…Your contribution is priceless.”

Executive Committee

Volusia Manufacturing Alliance