-

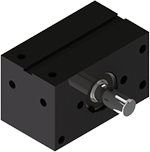

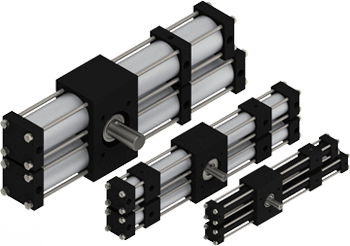

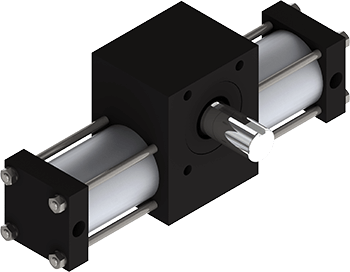

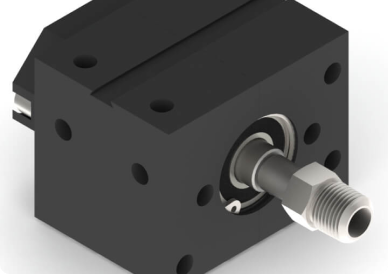

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

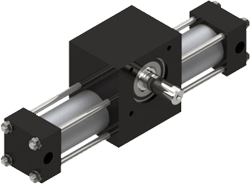

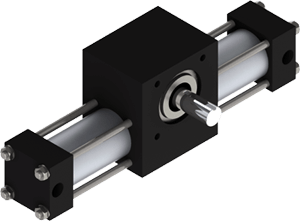

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

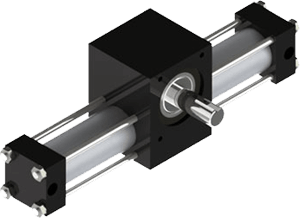

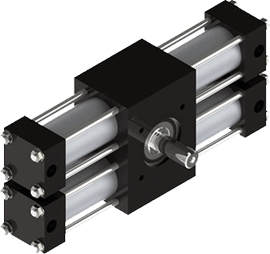

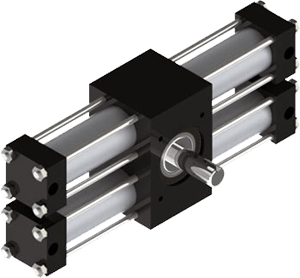

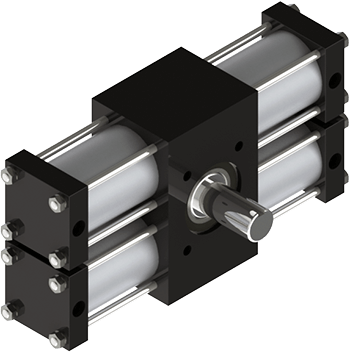

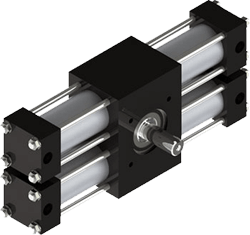

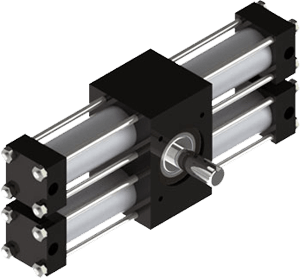

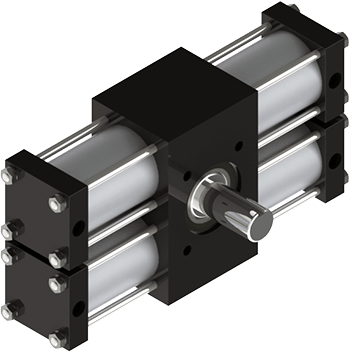

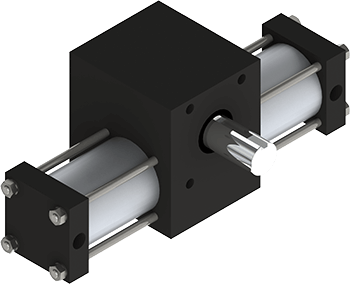

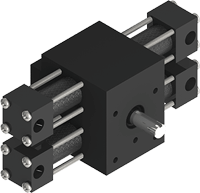

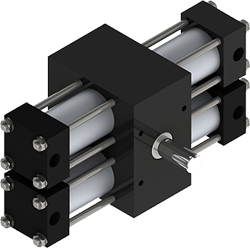

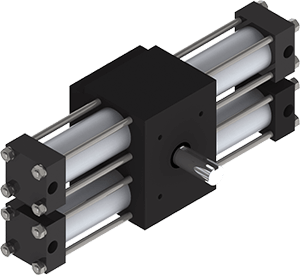

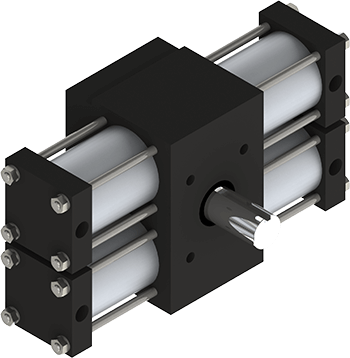

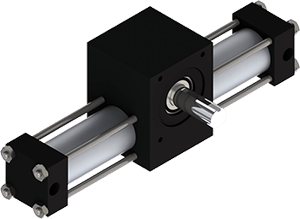

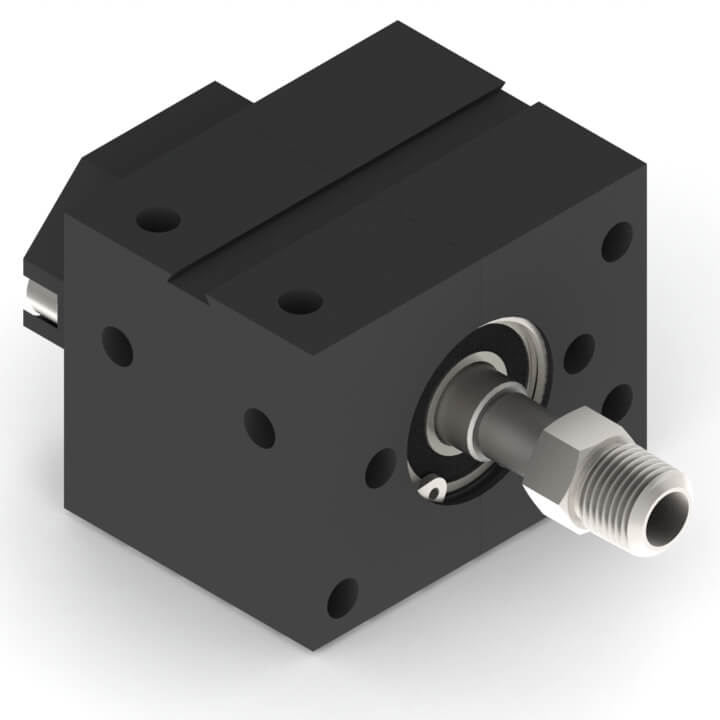

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

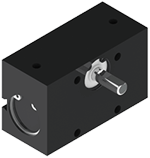

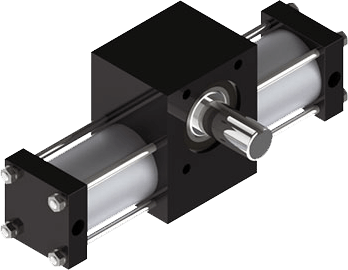

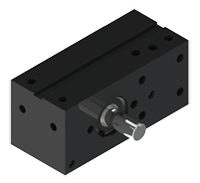

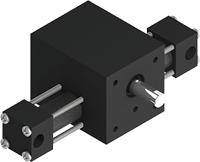

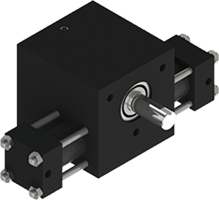

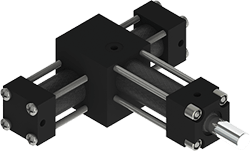

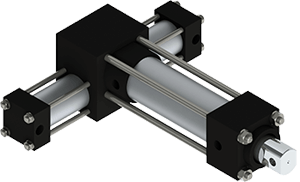

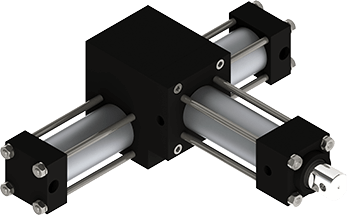

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

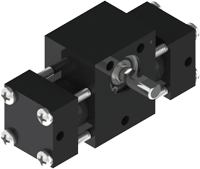

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

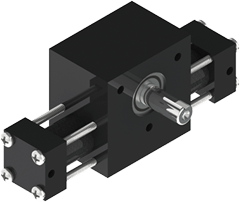

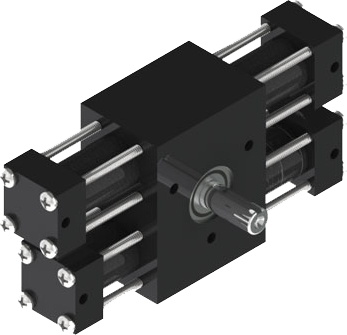

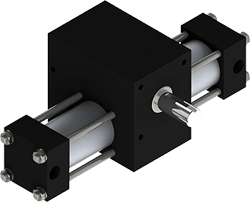

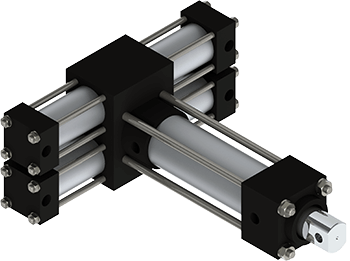

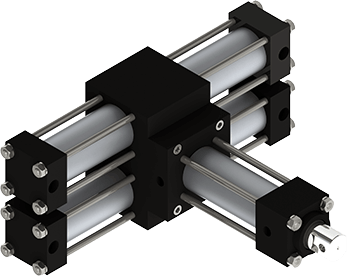

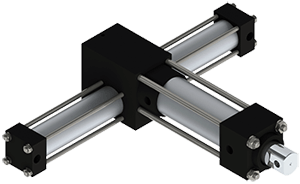

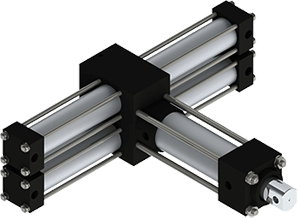

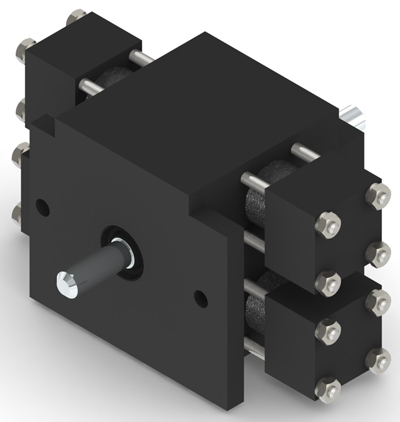

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

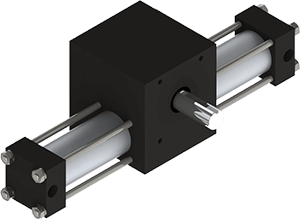

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

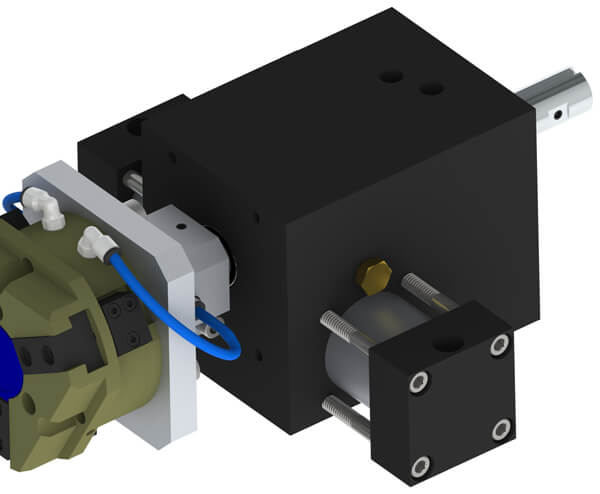

Special and Customized Actuators

Rotomation welcomes requests for special actuators because we understand how they can save our customers money by reducing the cost of extra parts or engineering time and/or improving their product or process. About 40% of the actuators we produce have some non-standard feature that improves our actuator’s ability to adapt to the load and/or working conditions to better fit our customer’s application.

For more specialized applications or actuators that do not conform to the same principles of our standard product line, our expert team of design engineers will work with you to establish specifications tailored to meet your specific requirements, then they will design, develop, and test a new product from the ground up if required. Whether you need one unit or thousands, we will produce what you need quickly and at a reasonable price.

We assign a special code in the part number of every special actuator that points to a unique bill of material that contains all the specifications and modifications necessary to reproduce a specific special actuator to simplify reordering. Upon request, we can also declare a special actuator to be proprietary to the OEM or distributor who ordered it originally to protect their investment.

Customized Actuators

If your application requires a simple modification to one or more parts on one of our standard units or you need us to make one of our standard actuators in some other material due to special environmental requirements, we’ll be glad to help you. See a few examples of recent customizations made for some of our customers below.

Custom Material Actuators

If your application requires one of our standard actuators to be made from a different material, including stainless steel, due to specific environmental requirements.

Customized Designed Actuators for OEM

If your application would be optimized by having an actuator designed from the ground up to suit your exact needs.

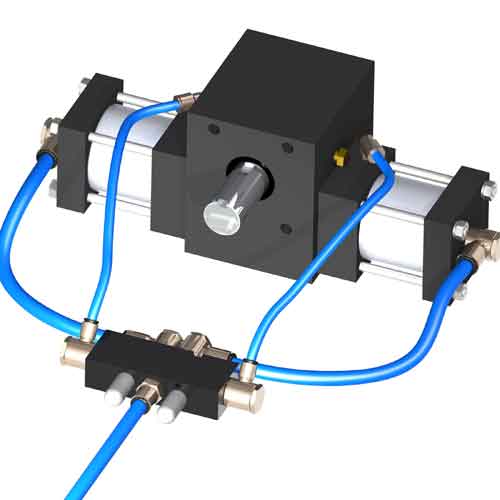

Special A032 rotary actuator with thru-shaft air feed and rear air manifold

(mouse over to compare to standard unit)

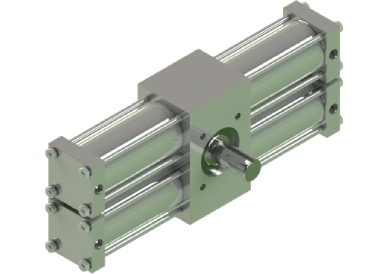

Special X12 indexing actuator with integrated mount flange, 8mm diameter plated shaft, and pharmaceutical-grade PTFE shaft seal for clean room manufacturing environment

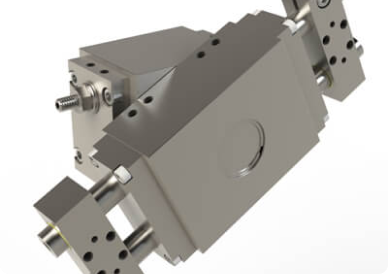

Special X3 indexing actuator with gripper adapter and integrated dual channel

air manifold, recessed end caps and custom shaft mounting adapter

Special setup for auto-run functionality – click on image for more information.

Need a CAD file? Our engineers are ready to help.

Request CADFind a distributor for Rotomation in your area.

DistributorsHave questions? Call us at 386-676-6377 or click.

Contact Us