-

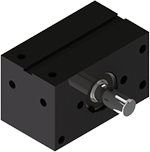

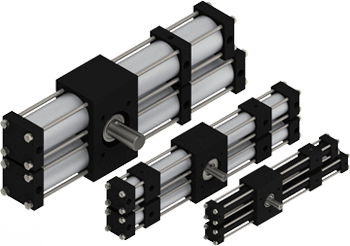

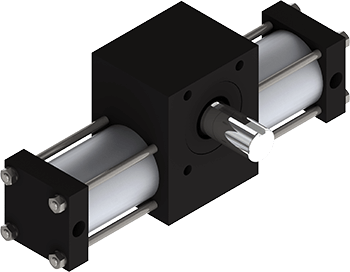

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

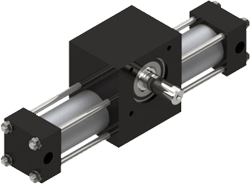

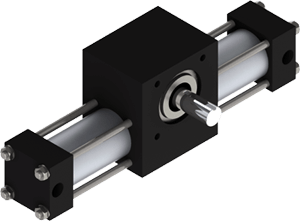

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

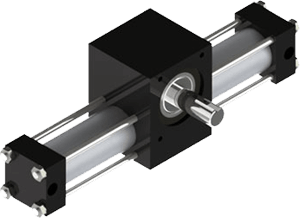

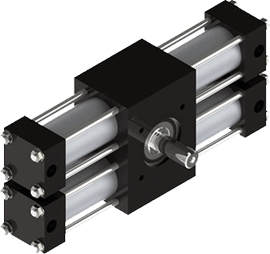

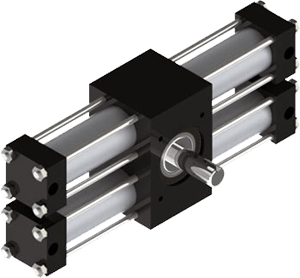

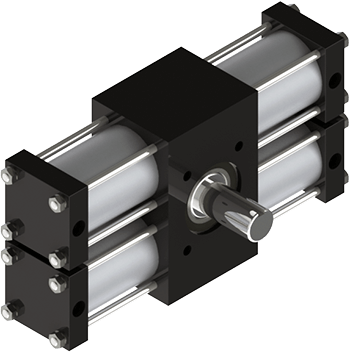

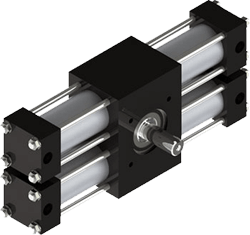

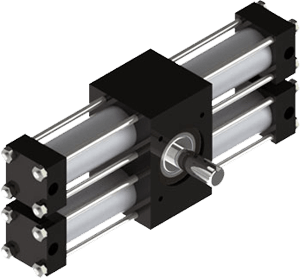

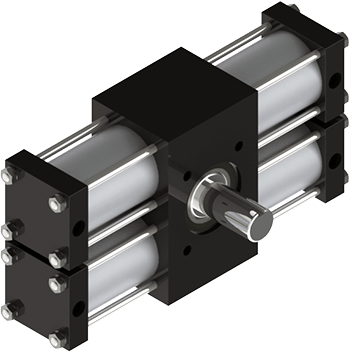

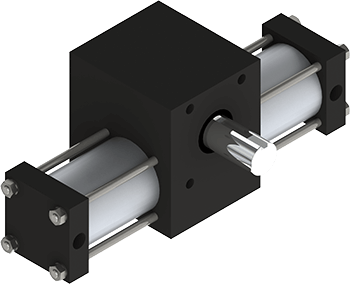

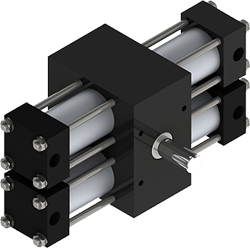

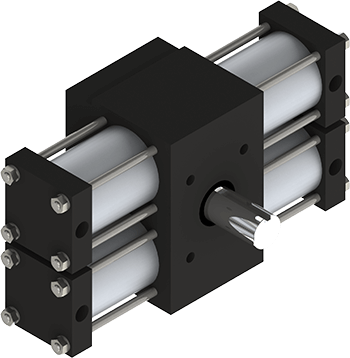

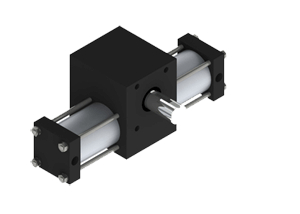

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

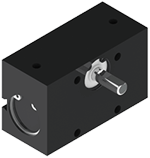

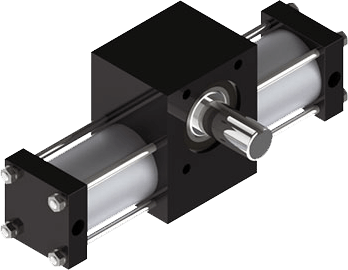

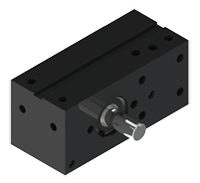

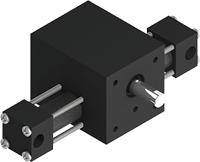

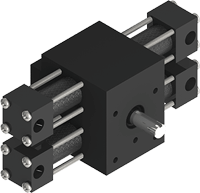

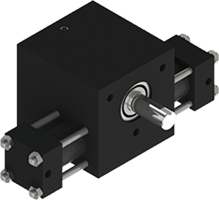

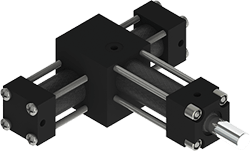

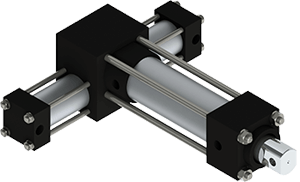

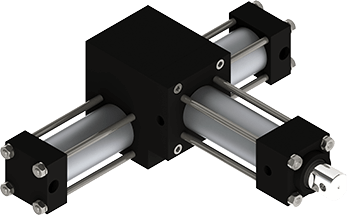

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

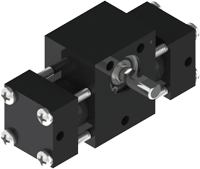

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

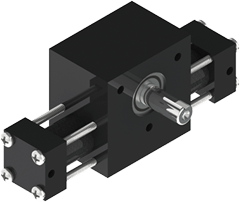

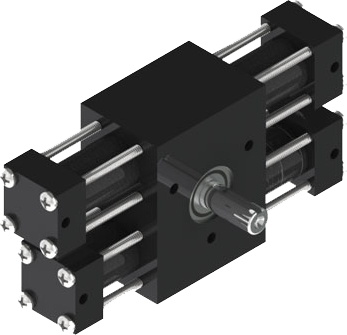

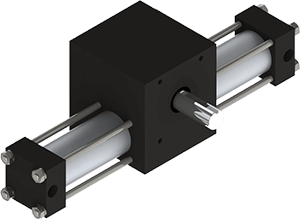

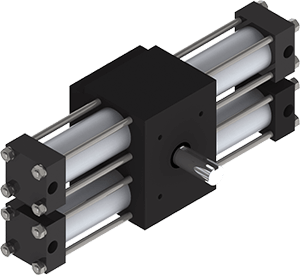

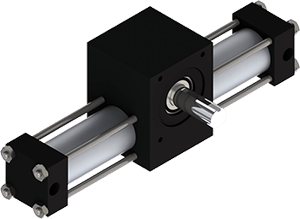

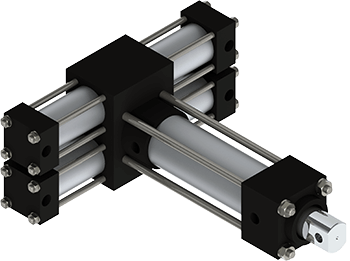

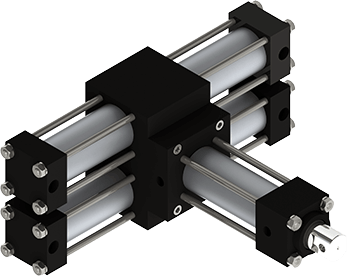

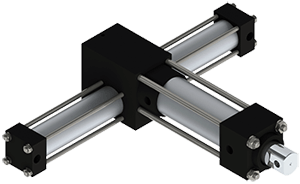

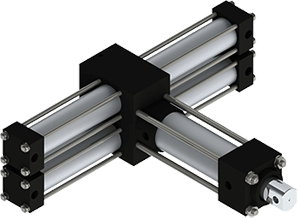

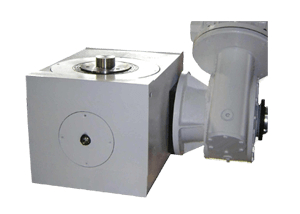

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

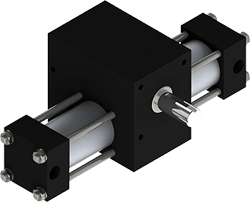

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

Indexing Drives For Automation

There are many applications in automation calling for repetitive rotary indexing. Some examples:

- star wheels

- conveyors

- escapements

- parts positioning for labeling, machining, inspection, etc.

- dispensing

There are at least three types of indexing drives that the engineer can choose between for these applications:

- Mechanical cam based drive

- Electrical servo based drive conveyors

- Pneumatic indexing drive

Cam Drives

Cam drives have been used for many years and are capable of good accuracy and dynamic control, high speed, and heavy loads. They are typically driven by a gearmotor, with one revolution of the input for each incremental motion of the output. They are best suited for continuous indexing which does not require the motor to be started and stopped for each cycle.

- Good dynamic control

- Good accuracy

- Large load capacity

- Durable, rugged construction

- Energy efficient

- High cost

- Not ideal for index-on-demand

- Inflexible operation

Servo Based Indexing Drives

A servo based indexing drive for such an application will include a servomotor with or without a gearbox, an encoder for position feedback, a motion controller, and an amplifier. Some of these components may be combined into integrated packages. There is normally a system controller overseeing the motion control, including human interface.

- Fully programmable speed, index, direction, acceleration, etc.

- High resolution

- Good dynamic control

- Flexible; can be repurposed easily

- Relatively complex and expensive

- Sensitive electronics and wiring must be shielded from adverse environments

- High level of know-how to design and repair

Pneumatic Indexing Drives See Our Indexers!

Pneumatic indexing drives, such as our indexing actuators, are simple, mechanical components capable of repetitive rotary indexing with no accumulating error. They are based on rack-and-pinion rotary actuators with the addition of one-way roller clutches and a ratchet and pawl system for stopping and registration. The motion is initiated by a directional control valve, so they are well suited to flexible automation where the index must occur on demand. They are robust and durable, but cannot match the controlled motion characteristics of the servo or cam drives.

- Low cost

- Very simple to design, implement, and maintain

- Robust construction can support the rotating load with its own bearings

- Operate in harsh environments

- Poor dynamic control of load

- No programmability

- Air consumption (only when moving)

Energy Consumption

The relative amount of energy these drives consume will depend on the duty cycle of the application. Cam and servo drives are both quite efficient but differ in that the servo uses full power to hold the load in place whereas the cam drive uses power only when driving the load. A pneumatic indexer uses compressed air, which is less efficient than an electric motor drive, but also uses no power when in the locked condition. So, if the duty cycle includes a high percentage of dwell time, the advantage shifts toward the cam and pneumatic systems.

If you have any questions for our engineers regarding our indexing actuators, call us at 386-676-6377 or CONTACT US to discuss your specific requirements.