-

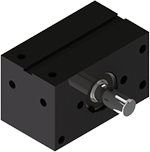

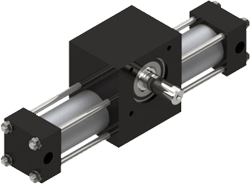

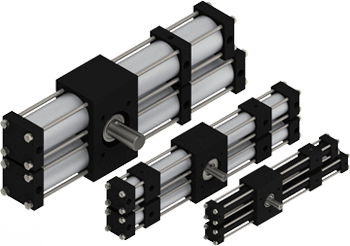

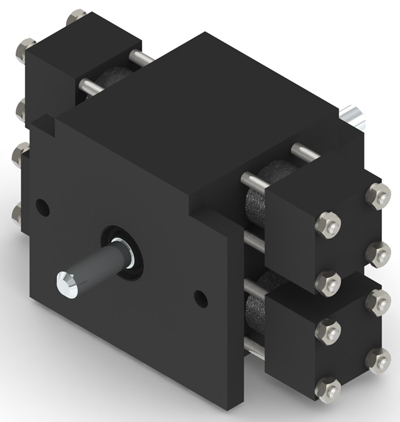

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

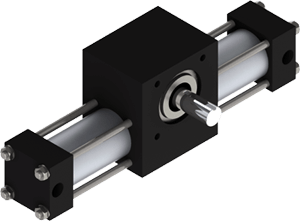

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

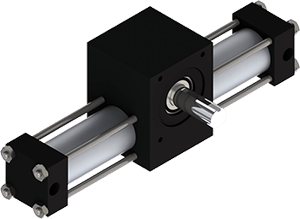

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

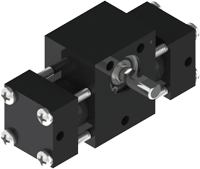

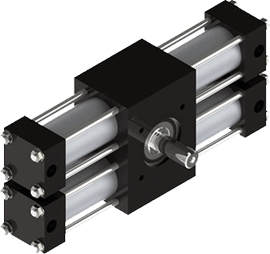

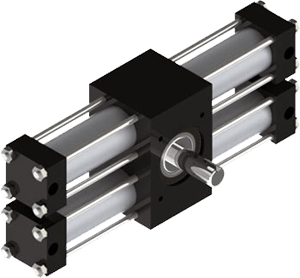

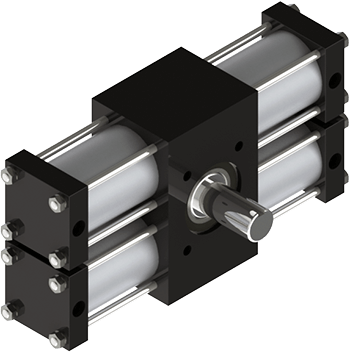

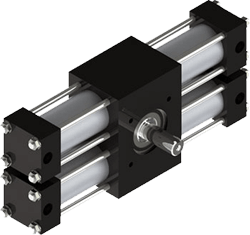

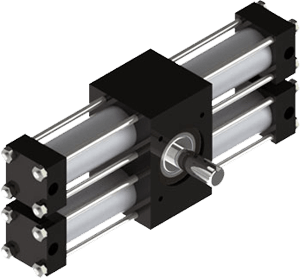

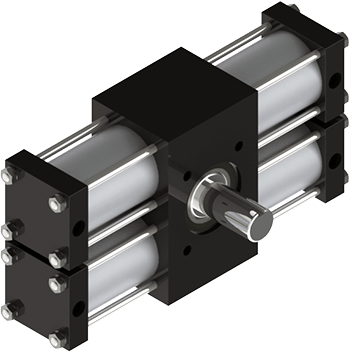

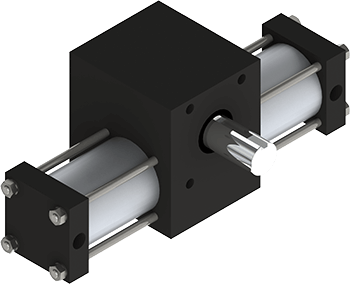

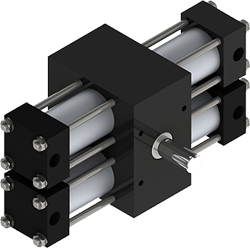

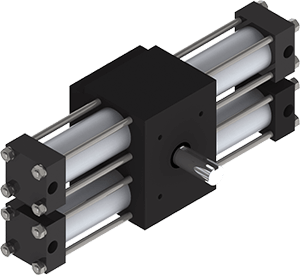

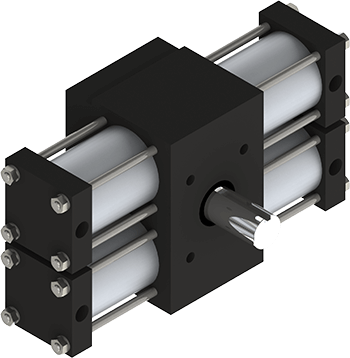

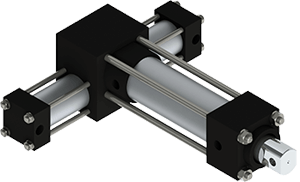

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

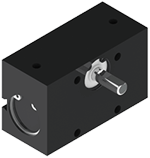

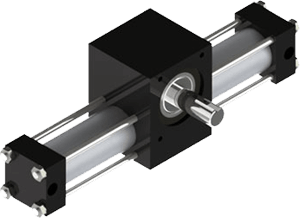

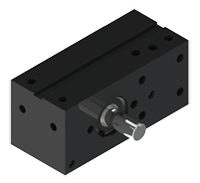

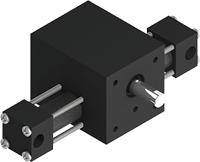

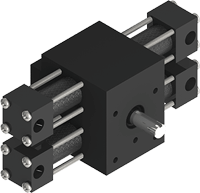

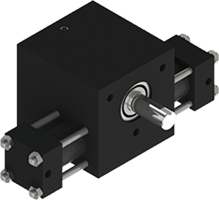

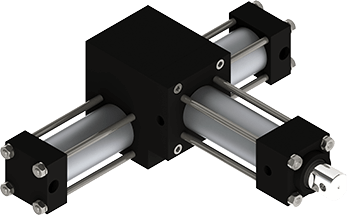

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

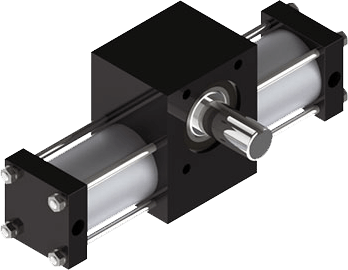

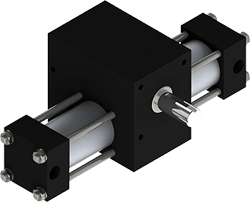

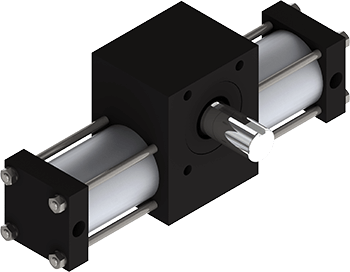

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

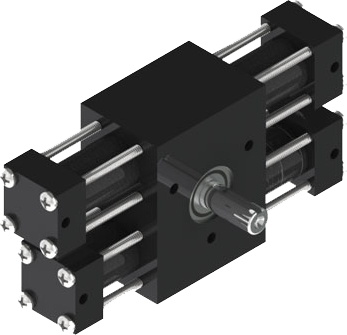

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

Special Rotary Actuators: Tailored Solutions for Engineers

In today’s fast-paced engineering world, having equipment tailored to your specific needs can be a game-changer. At Rotomation, we specialize in creating customized, custom-material, and custom-designed rotary actuators for OEM – all designed to optimize performance and efficiency for your unique applications.

Why Choose Custom Rotary Actuators?

Custom rotary actuators can significantly reduce costs by minimizing the need for additional parts and engineering time. They also enhance the functionality of your product or process. In fact, approximately 40% of the actuators we produce come with non-standard features requested by the engineer for a perfect fit, optimizing their design.

Specialized Solutions for Unique Applications

For applications that require more than just a tweak to our standard products, our expert team of design engineers is here to help. We will collaborate closely with you to establish specifications tailored to meet your exact requirements. From there, we design, develop, and test a new product from the ground up if needed. Whether you require a single unit or thousands, we ensure quick production at a reasonable price.

Simplified Reordering and Proprietary Protection

Every customized and custom-designed rotary actuator we produce is assigned a special code within its part number. This code links to a unique bill of materials detailing all specifications and modifications so that we can duplicate the product exactly. It also serves to track any changes over time that are made to the design per requests from the customer. Additionally, upon request, we can declare a customized and custom-designed rotary actuator proprietary to the OEM or distributor who initially ordered it, safeguarding your investment.

Customized Rotary Actuators: Sometimes, all you need is a simple modification to one or more parts of a standard unit. Changes to the shaft are the most common customization, so Rotomation stocks oversized pinion shaft blanks which allow us to quickly create special features at a minimal cost. Whether it is adapting the material for environmental reasons, changing mounting, porting, or control features to fit your needs, we are ready to assist.

Custom Material Rotary Actuators: Environmental requirements often necessitate the use of specific materials. If your application requires a standard actuator made from a different material, such as stainless steel, we have you covered.

Custom Designed Rotary Actuators for OEM: At Rotomation, we take pride in offering the largest selection of affordable customized rotary actuators. We realize, however, that some applications require a whole new design from the ground up. Our team can work with your specifications to design a custom rotary actuator to fit your project and your budget.

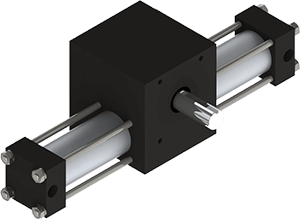

Real-World Examples of Our Custom Actuators

Below are a few examples of recent customizations we have made for our customers.

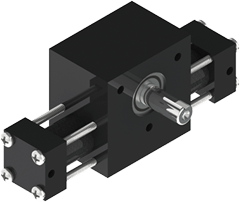

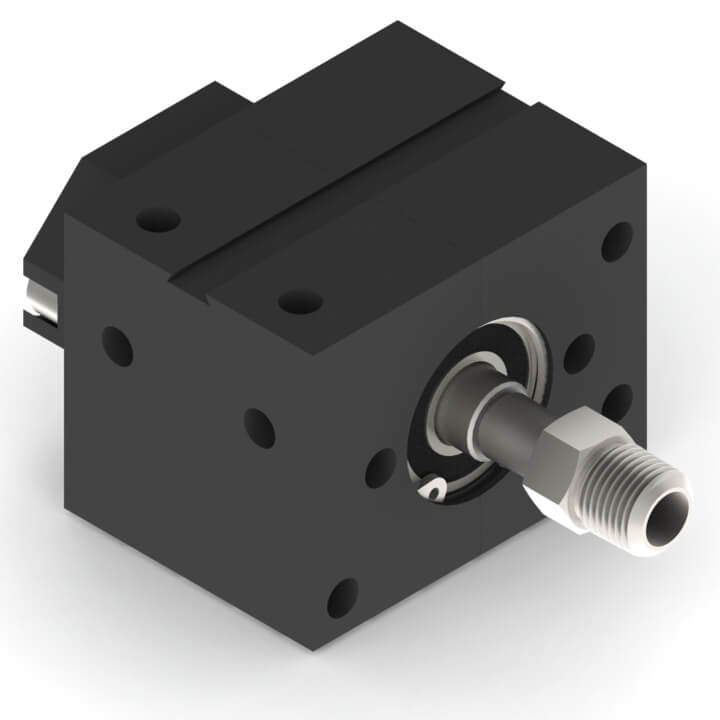

A032- X011 Thru-Shaft Vacuum Feed with Rear Manifold

This special A032 rotary actuator features a thru-shaft vacuum feed from a fixed manifold on the rear, avoiding a twisting hose. The same feature can be used to feed pressure to tooling mounted on the shaft.

A special X12 indexing actuator with hygienic features including an integrated mount flange, plated metric shaft, and a pharmaceutical-grade PTFE shaft seal, ideal for cleanroom manufacturing environments.

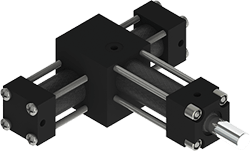

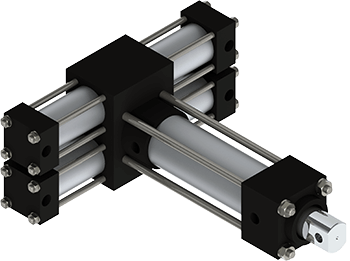

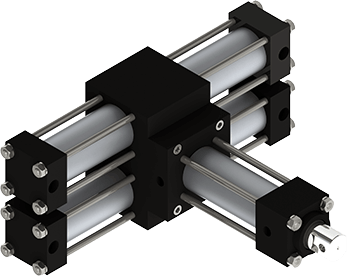

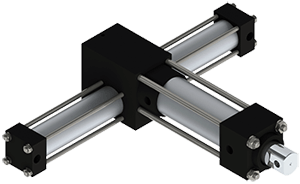

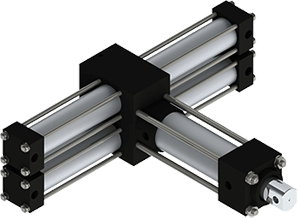

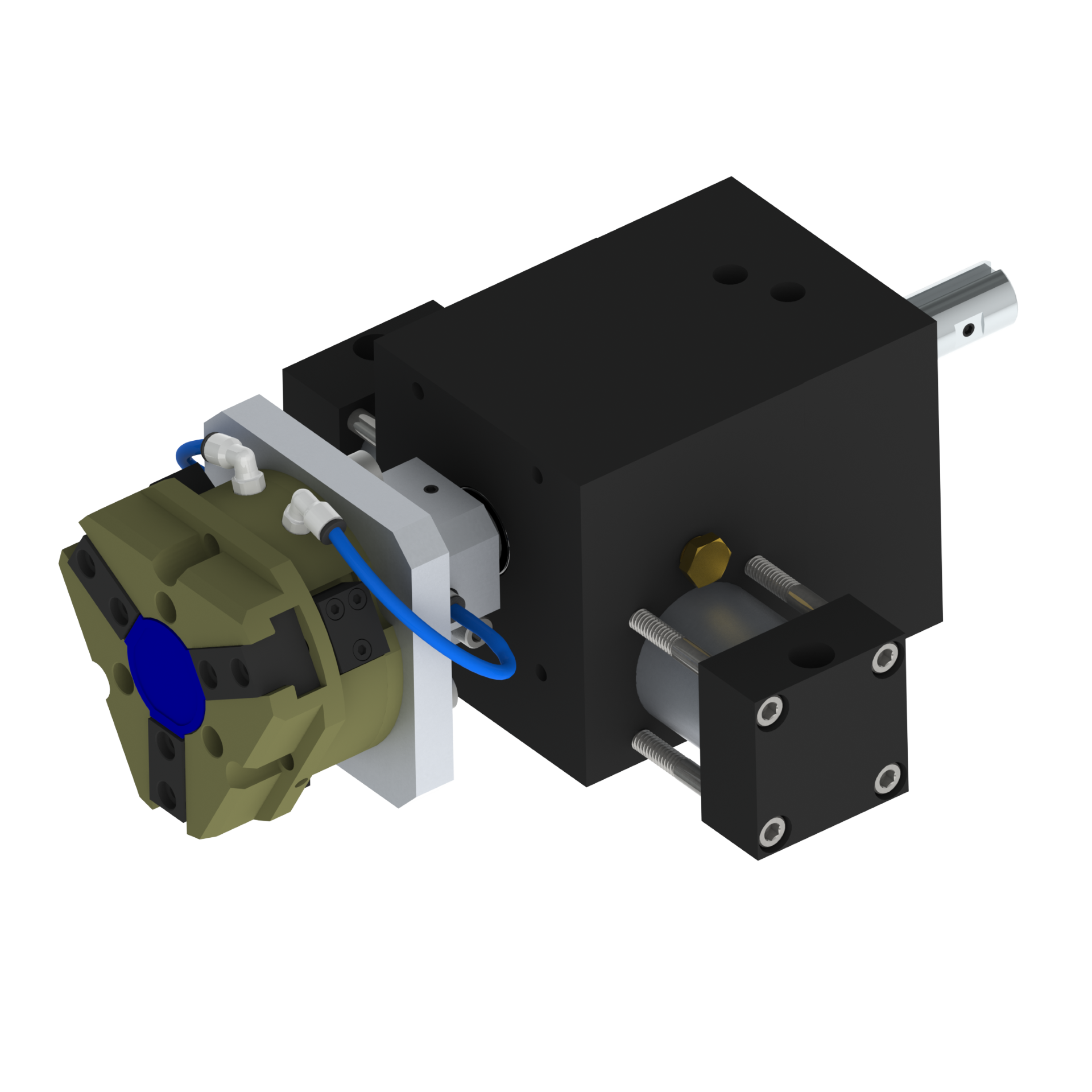

X3-X006

Our customer needed to index a part through three positions for laser marking. We equipped an X3 indexing actuator with a modified Shaft Mounting Adapter suited to their gripper, an integrated dual-channel air manifold, and recessed end caps to fit into a restricted space.

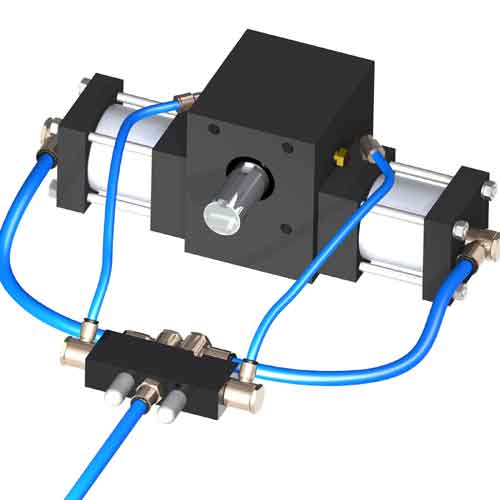

Pneumatic Signal Ports

These provide a pneumatic signal at the end of stroke, useful for controlling systems in environments that do not allow electrical circuits. With the addition of a piloted directional control valve, it becomes an auto-cycling system.

Conclusion

When it comes to custom rotary actuators, Rotomation stands out by offering tailored solutions that enhance efficiency and performance. We take pride in providing detailed, customer-centric designs that cater to the unique needs of engineers who are designing automated equipment.

Ready to optimize your next project? Contact us today to discuss your requirements and discover how our custom rotary actuator solutions can make a difference.

By understanding the intricacies of your application and providing precise, customized solutions, Rotomation helps you achieve unparalleled efficiency and performance. Reach out to us today and take the first step towards unlocking the full potential of custom rotary actuators.