-

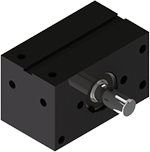

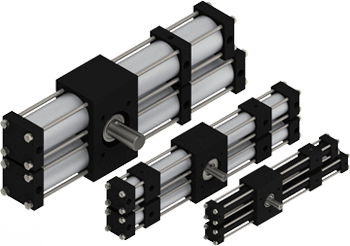

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

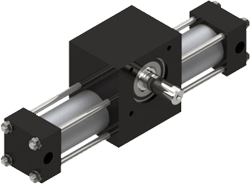

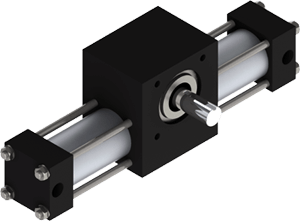

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

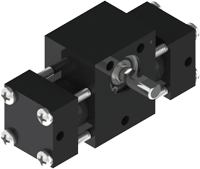

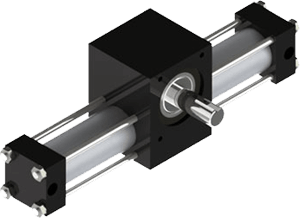

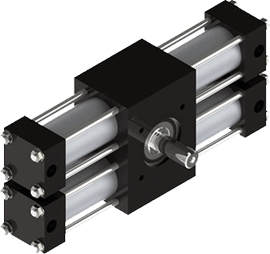

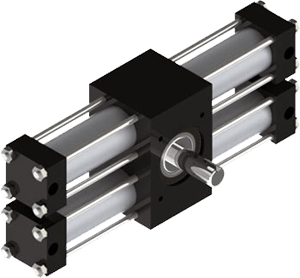

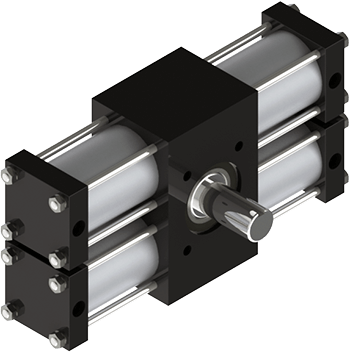

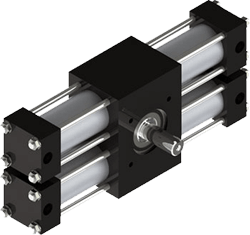

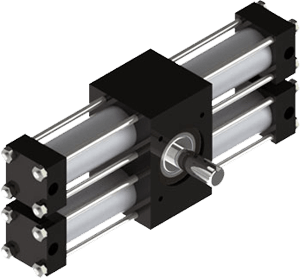

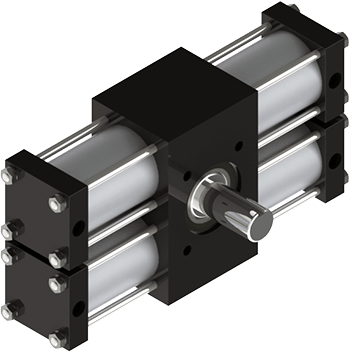

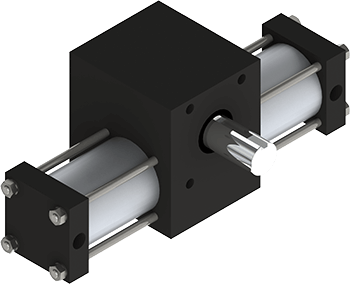

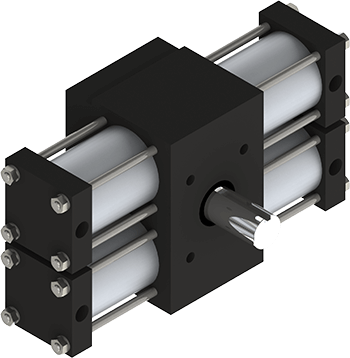

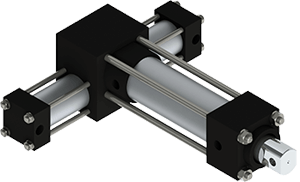

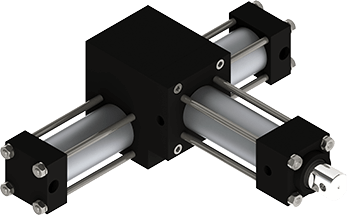

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

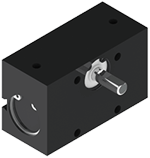

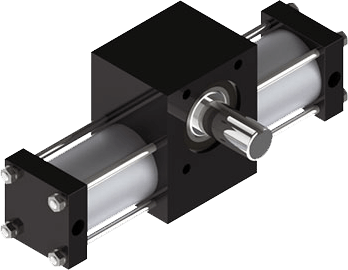

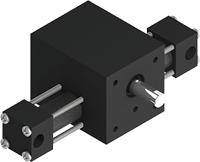

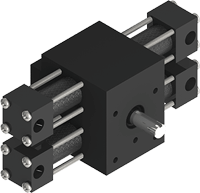

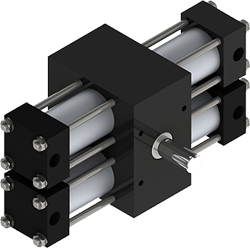

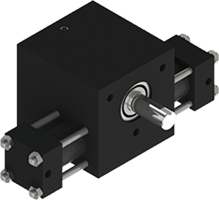

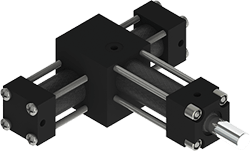

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

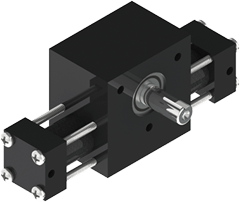

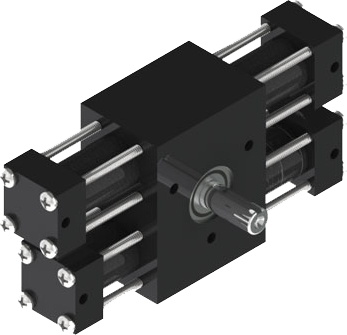

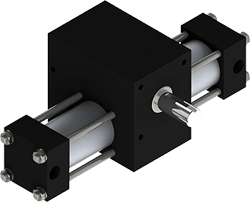

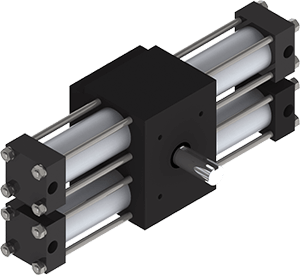

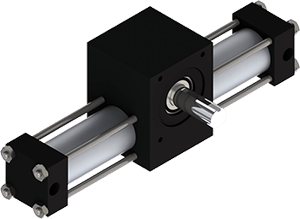

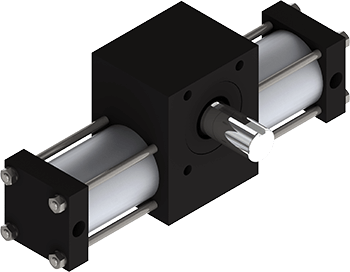

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

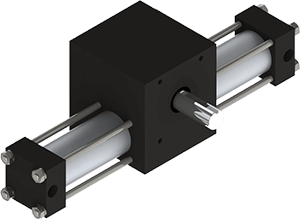

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

How Do Rotomation Indexing Actuators Work?

Rotomation’s indexing actuators provide accurate and repeatable rotary motion in increments to fixed stops with no accumulating error – essential for a wide range of automation tasks. Leveraging a unique design, our actuators ensure precise positioning and reliable performance, making them ideal for applications requiring high accuracy and efficiency.

How Rotomation Indexing Actuators Work:

Our indexing actuators operate on a principle similar to standard rotary actuators, utilizing pistons and a rack-and-pinion system to generate rotary motion. However, we’ve incorporated a specialized clutch/bearing mechanism for enhanced precision:

Clutch/Bearing System:

- The pinion features an integrated clutch/bearing, with separate needle sets for shaft support and directional gripping.

- During the drive stroke, the clutch engages the shaft, rotating it accurately.

- During the reset stroke, the clutch disengages, allowing the rack and pinion to return without rotating the shaft.

- A second clutch prevents backward shaft rotation.

Ratchet and Pawl for Precise Stops:

- A ratchet, with teeth corresponding to the desired index angles (e.g., 4 teeth for 90-degree indexing), ensures accurate stops.

- A spring-loaded pawl interacts with the ratchet teeth, precisely halting shaft rotation.

- This mechanism provides a locked position, preventing both forward and reverse rotation.

Consistent Accuracy:

- The actuator’s design ensures accuracy is determined solely by the ratchet, not the stroke length.

- The actuator remains locked while part processing takes place, then the directional control valve is shifted to initiate a reset stroke to prepare for the next index.

Key Features and Benefits:

- High Precision Indexing: Achieve consistent and accurate positioning for critical applications.

- Reliable Performance: Robust design ensures long-lasting operation and minimal maintenance.

- Flexible Control: Easily integrate with existing control systems for seamless automation.

- Adjustable Speed Control: Flow control valves allow for precise speed adjustments, preventing harmful impacts.

- Feedback Options: Magnetic switches or extended pawl shafts provide reliable position feedback.

- Manual Override Capability: Utilize the free-wheeling reset mode for manual adjustments or jam clearing.

- Versatile Applications: Suitable for a wide range of industries and automation tasks.

Applications:

Rotomation indexing actuators excel in various applications, including:

- Rotary tables

- Indexing conveyors

- Starwheels

- Walking beams

- Carousels

- Packaging machinery

- Automated testing

Selection Considerations:

- Inertia-Dominated Loads: Size the actuator based on its stopping capacity, focusing on inertia and kinetic energy.

- Torque-Dominated Loads: Utilize dual rack indexers for applications requiring high torque relative to inertia, such as conveyors with high friction or forming operations.

- Consult our catalog or contact our engineers for guidance.

Control and Feedback:

- Speed Control: Use flow control valves for precise speed adjustments, avoiding high-impact stops.

- Cushioning: Apply cushions for smoother stops, especially when friction is present.

- Reset Stroke Control: Implement cushions or bumpers to minimize impacts during the reset stroke.

Feedback Options:

- Magnetic switches for end-of-stroke indication.

- Extended pawl shafts for precise position sensing.

- Encoder adaptation available for absolute position feedback.

Video: See the X1 Indexing Actuator in Action

Ready to optimize your automation processes with Rotomation indexing actuators? Contact our experienced engineers today for expert assistance and customized solutions.