-

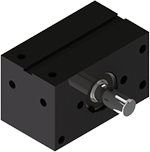

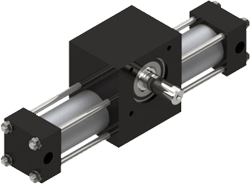

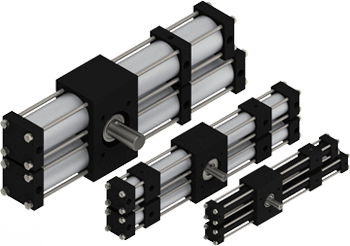

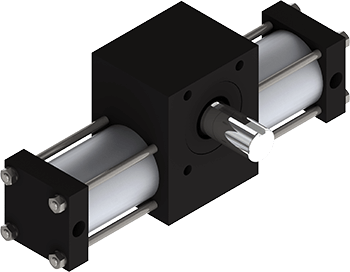

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

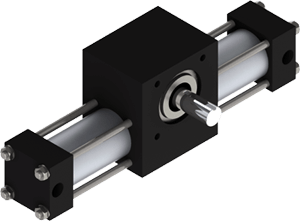

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

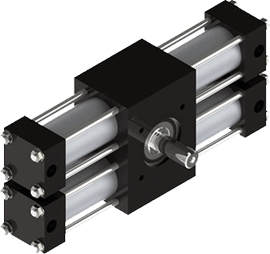

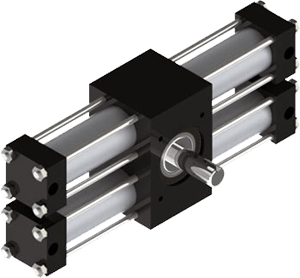

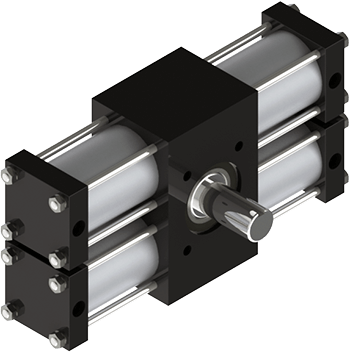

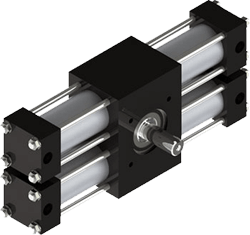

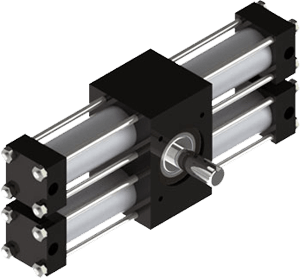

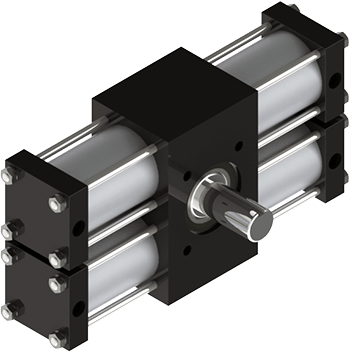

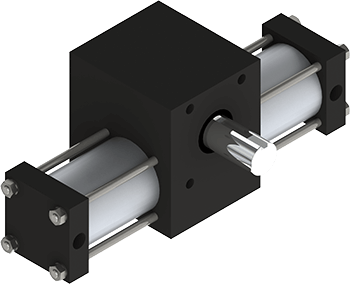

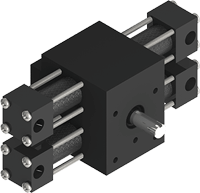

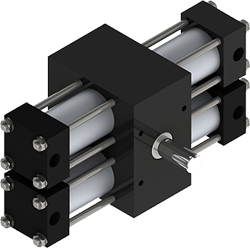

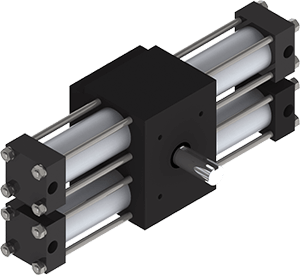

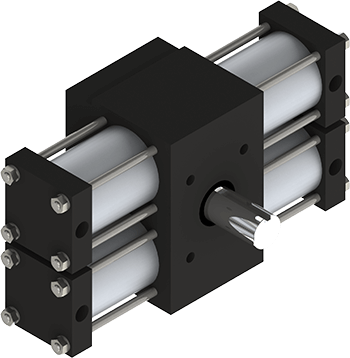

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

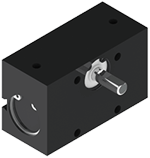

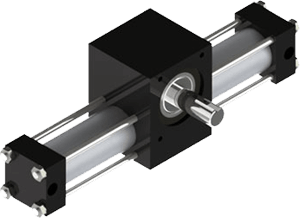

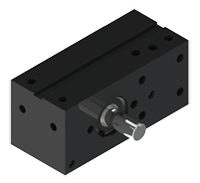

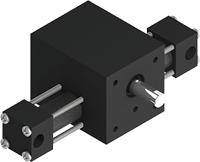

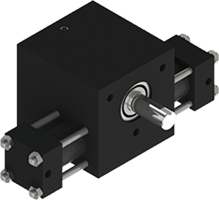

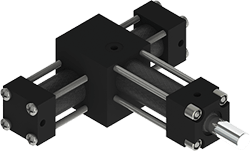

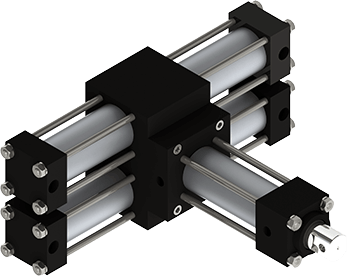

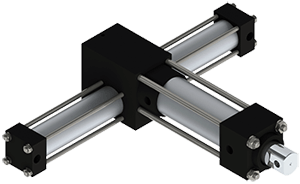

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

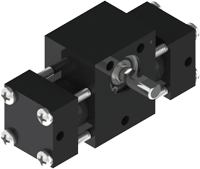

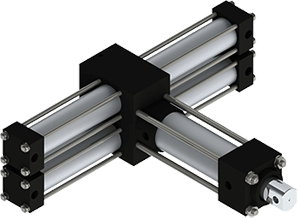

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

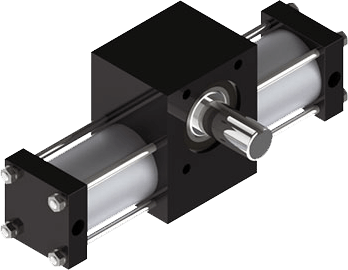

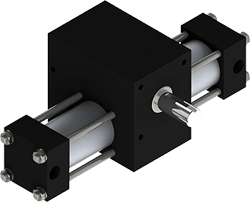

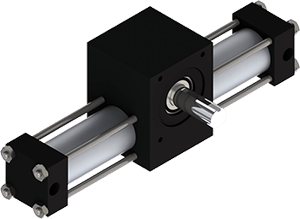

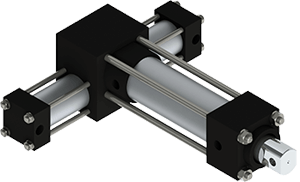

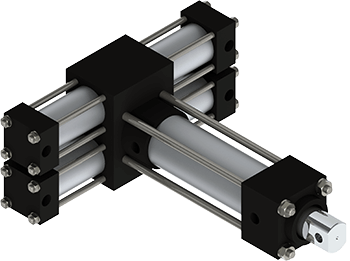

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

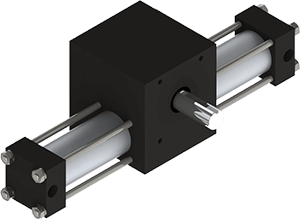

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

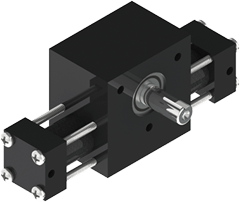

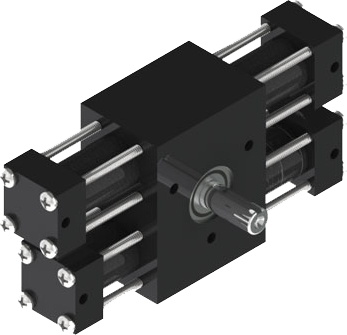

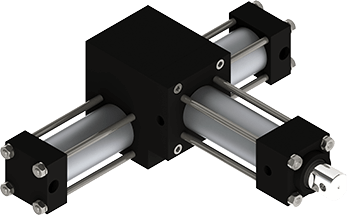

Understanding Stepping Actuators

A Look into Rotomation’s Pneumatic Technology

In industrial automation, engineers need a wide range of products to craft optimal solutions. Why? Because every automation challenge is unique. When choosing actuators for automation, the starting point is the type of motion needed; linear, reciprocating rotary, indexing, or combinations of these. Then factors like speed, accuracy, payload, environmental conditions (temperature, dust, and moisture), safety, and budget all dictate specific component needs. You can’t just force a “one size fits all” solution.

Stepping actuators are a powerful and specific solution for certain applications, and Rotomation stands out as a leader in pneumatic automation, having perfected the design and function of these vital components. Let’s dive deeper into Rotomation’s stepping actuators, exploring their capabilities, advantages, and why they might be the ideal fit for your next project.

What is a Stepping Actuator?

A stepping actuator provides unidirectional rotational movement in incremental steps without fixed hard stops. Stepping actuators are ideal for applications requiring consistent torque application across a specific angle without the need for absolute positional stops.

Why Choose Stepping Actuators

Stepping actuators excel in applications characterized by low inertia and high friction. They’re particularly well-suited for tasks like incremental conveyors or pinch rollers used to feed sheets or spooled materials. A key advantage over mechanical indexing drives is their versatility: steppers can be fitted with rotation adjusters, or multiple, selectable increments of rotation, providing greater flexibility for your operational needs.

What Make’s Rotomation’s Stepping Actuators Unique?

Rotomation’s stepping actuators stand out from the competition due to their fully integrated design. Unlike other products that rely on add-on clutch housings, Rotomation seamlessly incorporates clutches directly into the unit, utilizing the existing, heavy duty shaft bearings. This provides exceptional support for your load and ensures a compact design, maintaining the same dimensions as their corresponding rotary actuators.

These actuators are built with quality in mind, featuring black-anodized aluminum bodies, precision-ground case hardened shafts, durable ball bearings, and corrosion-resistant stainless-steel hardware. This robust construction ensures reliable and long-lasting performance.

Ideal Scenarios for Stepping Actuators

The unique stepping motion and robust design make Rotomation’s actuators perfectly suited for applications where low inertia and high friction are present, or where adjustable rotation is required. They can be applied across a diverse range of industries and are particularly effective in scenarios such as:

- Pinch Roller: Feeding material from spool incrementally. Adjustable rotation allows changes to the length of material fed.

- Indexing Conveyor: Stepping actuators can offer a very simple, rugged drive for an indexing conveyor that does not have to position products precisely relative to multiple fixed stations, but which need to stop for product added to or removed from the conveyor. Examples include baking, meat processing, and spraying.

- Mixing (Stirring) of Viscous Products

- Boost Torque of Indexing Mechanism

- Precise Indexing by Addition of External Stop/Registration Components

- Peristaltic Pump Drive

Customization and Versatility

Rotomation understands that no two applications are exactly alike. Therefore, our stepping actuators are highly configurable for remarkable versatility. You can equip them with rotation adjusters, allowing you to fine-tune the degree of each incremental step. They can also be configured to provide multiple, selectable increments of rotation, giving you greater control over the motion profile.

The shared dimensions with corresponding rotary actuators make integration seamless, simplifying design and assembly for engineers. Beyond the core features, Rotomation offers a range of common options to tailor the actuator to your specific needs. These include different shaft types to accommodate various loads and connections, your choice of rotation direction, and bumpers for cushioning and noise reduction. Integrated flow controls allow for precise speed adjustments, while magnetic switches enable accurate position sensing for advanced automation. For operations in extreme conditions, high-temperature seals ensure continued performance and longevity.

In conclusion, Rotomation’s stepping actuators represent a blend of robust construction and versatile functionality. They offer an ideal solution for applications demanding unidirectional, incremental motion with high reliability across a multitude of industries. By understanding the unique benefits and customization options, you can leverage Rotomation’s technology to enhance the performance and efficiency of your automated systems.

For more information, you can visit the Rotomation product page for stepping actuators.