-

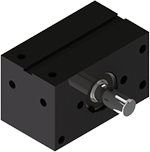

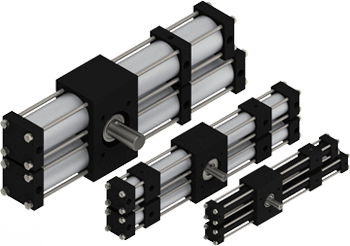

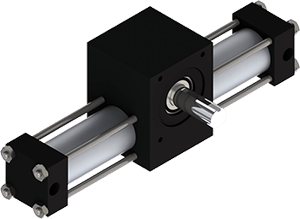

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

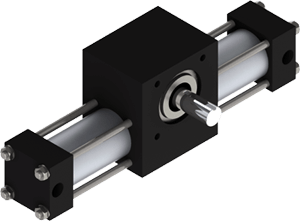

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

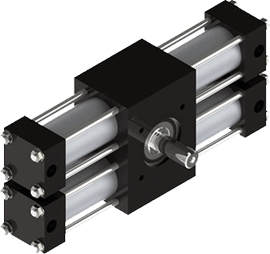

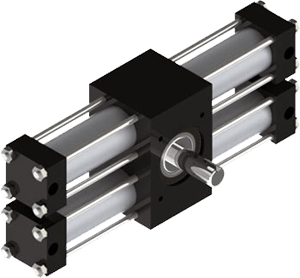

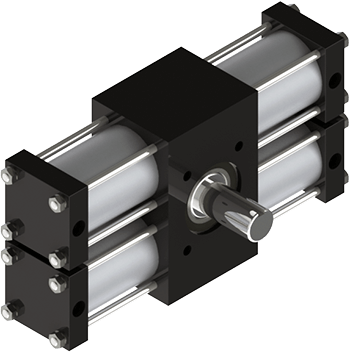

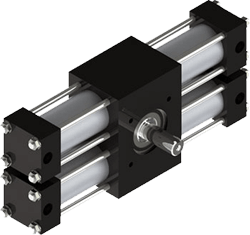

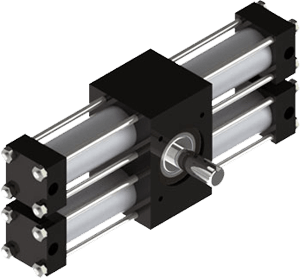

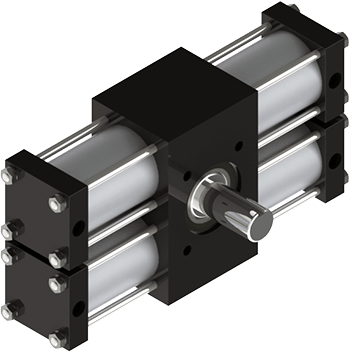

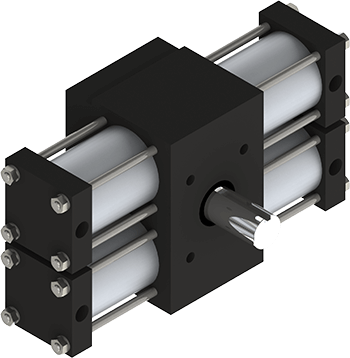

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

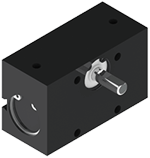

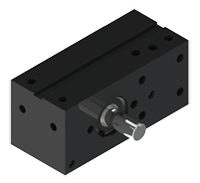

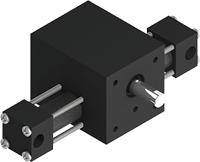

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

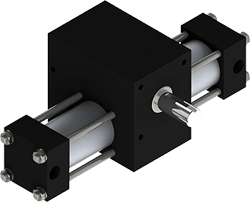

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

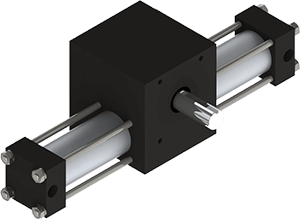

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

Multi-Motion Actuators by Rotomation: Precision for Automated Solutions

We at Rotomation understand the importance of accuracy in automated processes. Each Multi-Motion Actuator we build is designed for industries like automotive, pharmaceuticals, and food & beverage, where precision handling is crucial. With robust design and flexibility, we ensure that our actuators deliver smooth and efficient motion while offering custom solutions tailored to your specific production needs.

We at Rotomation understand the importance of accuracy in automated processes. Each Multi-Motion Actuator we build is designed for industries like automotive, pharmaceuticals, and food & beverage, where precision handling is crucial. With robust design and flexibility, we ensure that our actuators deliver smooth and efficient motion while offering custom solutions tailored to your specific production needs.

Advanced Design and Capabilities

Here at Rotomation, every Multi-Motion Actuator features an innovative design that guarantees precision across a wide range of operations. These actuators excel at moving objects between two or more positions, a necessity in many automated production systems.

With adjustable rotational motions, they ensure repeatability and accuracy—making them perfect for handling delicate materials or working in high-speed production lines. Whether it’s a repetitive task in a packaging line or a precise movement in semiconductor manufacturing, our Multi-Motion Actuators ensure reliable, flawless performance.

Each Multi-Motion Actuator provides multi-position capabilities that allow for more flexible configurations, giving engineers the option to adapt the actuators to different manufacturing environments. Whether you need a single rack or dual rack design, Rotomation provides options that cater to your exact requirements, offering precision and adaptability across multiple industries.

Pneumatic Multi-Motion Actuators: Multi-Motion Solutions for Automated Efficiency

You’ll find pick and place (or multi motion) actuators in manufacturing and packaging operations to electronics and pharmaceuticals. At the core of these systems are pneumatic Multi-Motion Actuators, also known as multi-motion actuators. These versatile devices provide the precise and controlled movements needed for efficient material handling. This article delves into the capabilities and benefits of these actuators, highlighting their adaptability for diverse applications.

Understanding Pick and Place and Multi-Motion Actuators

Multi-Motion Actuators are engineered to perform both linear and rotary motion, making them perfect for tasks that require lifting, rotating, and placing objects. The term multi-motion actuators reflects their ability to execute these movements independently. This versatility stems from their unique construction, which combines a rotary section with a linear cylinder. This allows for a single actuator to perform pick and place motion for general applications where reliability and durability are important.

Why Choose Pneumatic Multi-Motion Actuators?

Pneumatic Multi-Motion Actuators offer several advantages that make them a preferred choice for automation:

- High Speed and Force: Pneumatic systems are known for their rapid response times for applications demanding quick, powerful movements in multi-motion operations.

- Simplicity and Reliability: With fewer components than electromechanical counterparts, pneumatic actuators offer increased reliability and reduced maintenance, ensuring consistent multi-motion accuracy.

- Cost-Effectiveness: Pneumatic systems generally have a lower initial cost and their robust construction minimizes maintenance, contributing to long haul cost savings for multi-motion systems.

- Compact Size: Multi-Motion Actuators are designed for compact spaces, minimizing the overall footprint of the automation system, a crucial factor in many multi-motion applications.

Types of Pneumatic Multi-Motion Actuators

Rotomation offers two primary types of pneumatic Multi-Motion Actuators:

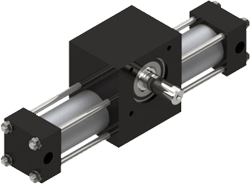

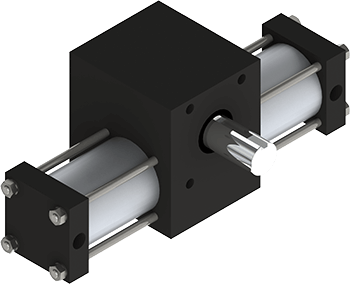

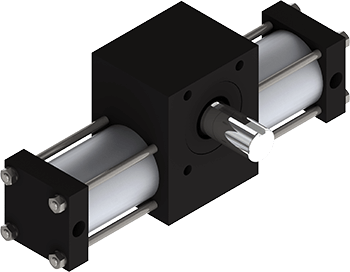

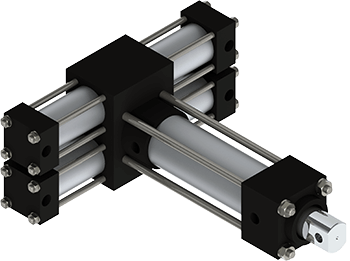

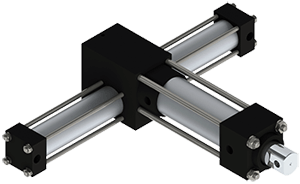

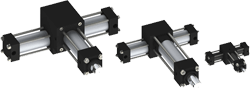

Single Rack Multi-Motion Actuators

These actuators utilize tie rod construction, known for its durability and configurability. They are fully rebuildable, making them a sustainable and cost-effective solution for general multi-motion applications where reliability is paramount.

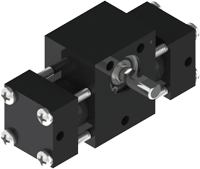

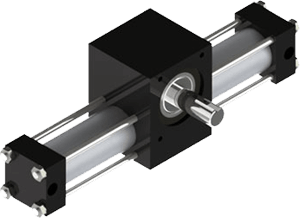

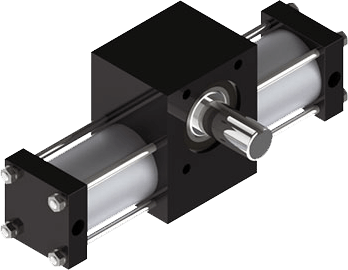

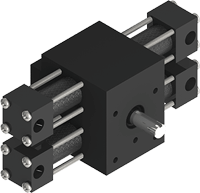

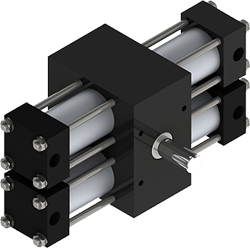

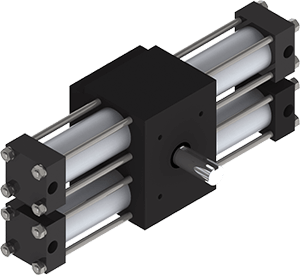

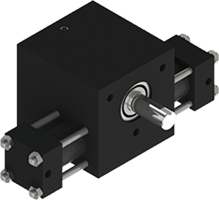

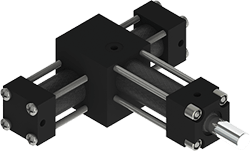

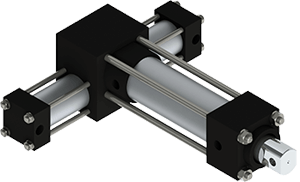

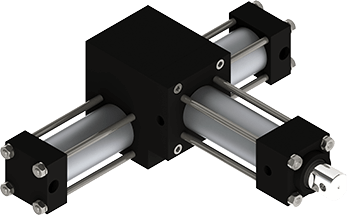

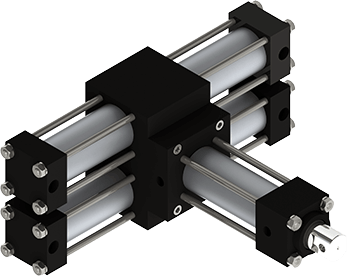

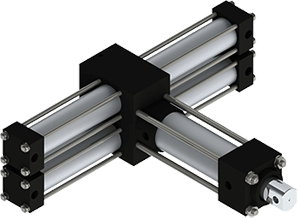

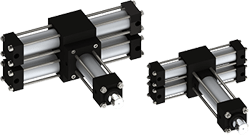

Dual Rack Multi-Motion Actuators

Dual rack actuators provide double the torque and reduce backlash at the ends of rotation without increasing the actuator's footprint. This enhanced performance makes them suitable for demanding multi-motion applications that require high precision and repeatability. Dual rack actuators also open up the possibility of providing multiple rotary positions. Rotomation can produce dual rack multi-motion actuators with two, three, four, or five rotary positions. One use for this feature is in sorting applications; pick parts up from one location, deposit them in any one of multiple bins depending on the status of the part.

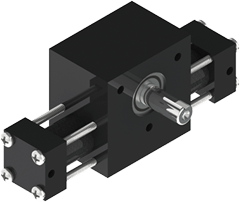

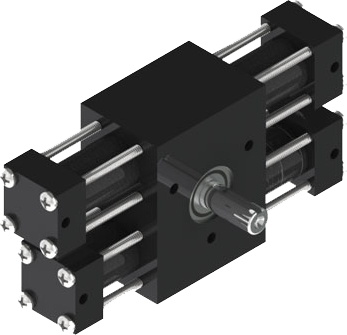

- Indexing Multi-Motion Actuators: A truly unique product, the Rotomation Nitpicker combines linear motion with indexing rotary motion. Index steps can be selected between 12 and 360 degrees, with no accumulated error. They can be used to transfer parts from station to station using a single actuator.

Need a CAD file? Our engineers are ready to help.

Request CADFind a distributor for Rotomation in your area.

DistributorsHave questions? Call us at 386-676-6377 or click.

Contact Us