-

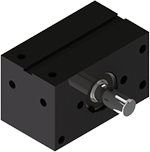

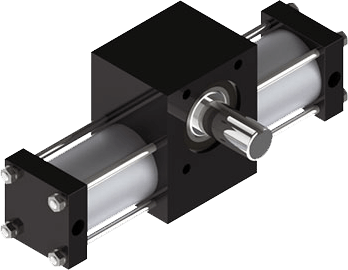

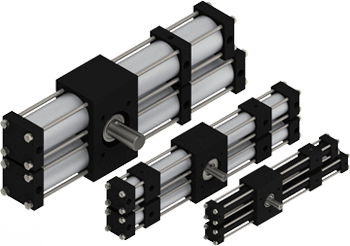

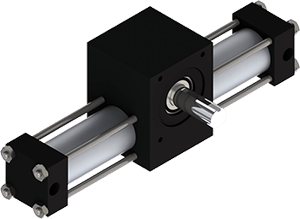

Rotary Rotary ActuatorsCompactA032*80psi

Rotary Rotary ActuatorsCompactA032*80psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 1/4" or 3/8"

DiameterAL75*80psi Torque: 7-14 in-lb*

Torque: 7-14 in-lb*

Shaft: 1/4"

DiameterA752*80psi Torque: 35 in-lb*

Torque: 35 in-lb*

Shaft: 3/8"

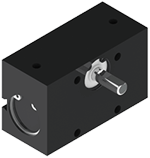

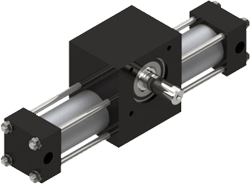

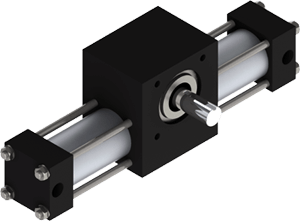

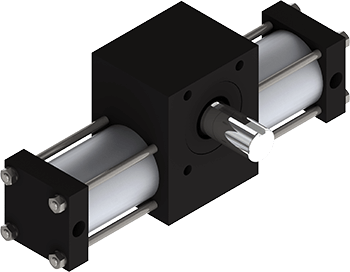

DiameterSingle Rack Tie-RodA01*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 3/16" or 1/4"

DiameterA1*80psi Torque: 12 in-lb*

Torque: 12 in-lb*

Shaft: 1/4" or 3/8"

DiameterA2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA3*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA4*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft: 1" or 1 1/8"

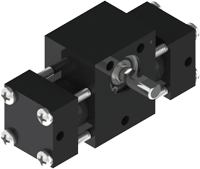

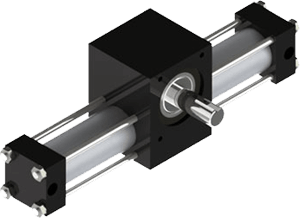

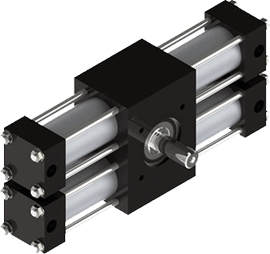

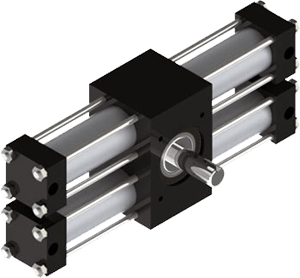

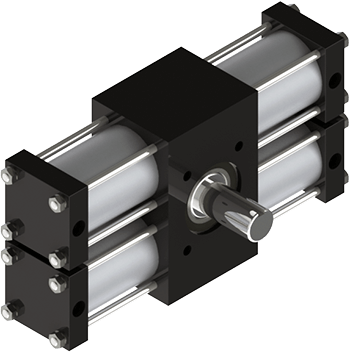

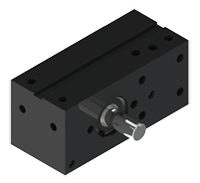

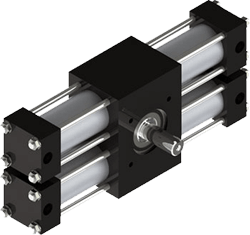

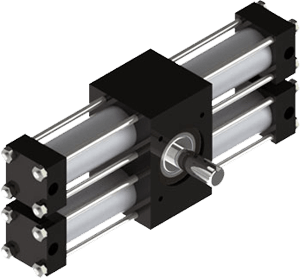

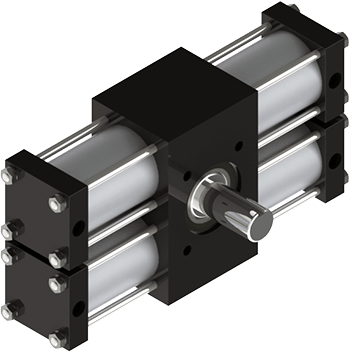

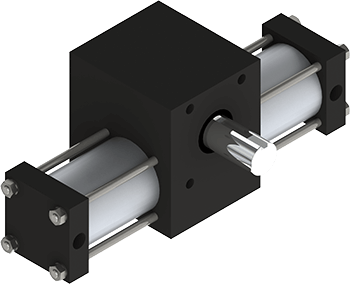

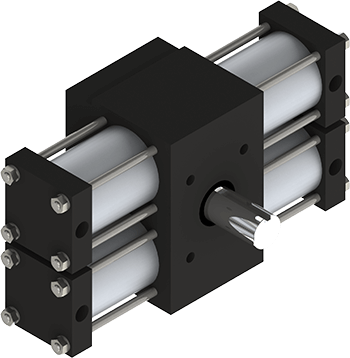

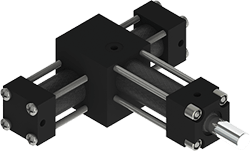

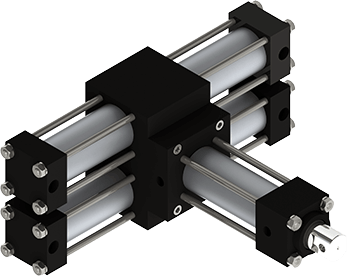

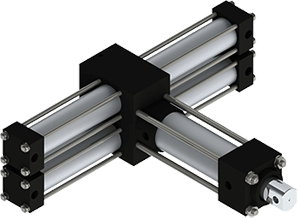

DiameterDual Rack Tie-RodA12*80psi Torque: 24 in-lb*

Torque: 24 in-lb*

Shaft: 1/4" or 3/8"

DiameterA22*80psi Torque: 78 in-lb*

Torque: 78 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 238 in-lb*

Torque: 238 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 545 in-lb*

Torque: 545 in-lb*

Shaft: 1" or 1 1/8"

Diameter -

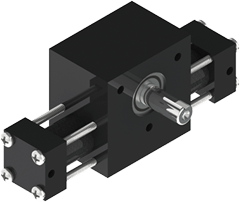

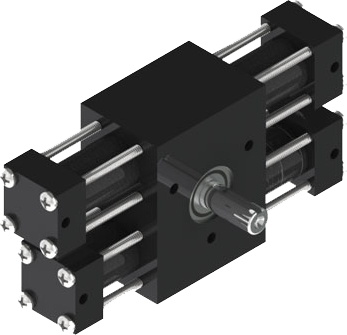

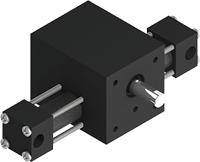

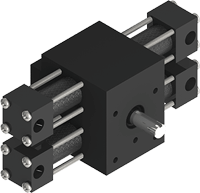

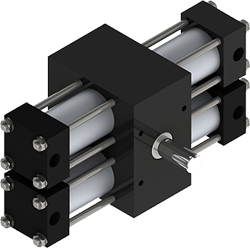

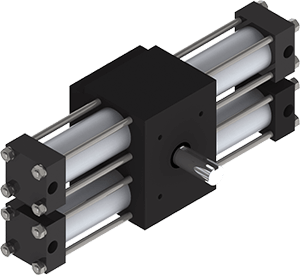

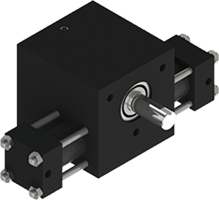

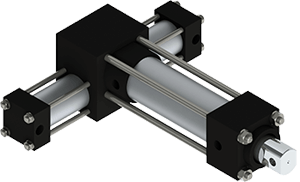

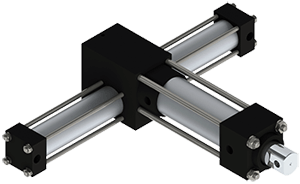

Multi-Position Multi PositionThree Position ActuatorsA032*80psi

Multi-Position Multi PositionThree Position ActuatorsA032*80psi Torque: 6 in-lb*

Torque: 6 in-lb*

Shaft: 1/4" or 3/8"

DiameterA12*80psi Torque: 12 in-lb

Torque: 12 in-lb

Shaft: 3/8"

DiameterA22*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1/2"

DiameterA32*80psi Torque: 119 in-lb*

Torque: 119 in-lb*

Shaft: 3/4"

DiameterA42*80psi Torque: 277 in-lb*

Torque: 277 in-lb*

Shaft 1 or 1 1/8"

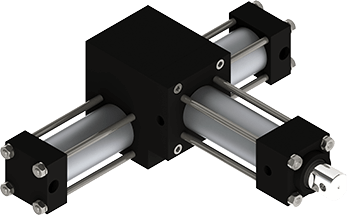

Diameter4 or 5 Position ActuatorsFour or Five Position*80psi Torque: 12-277 in-lb*

Torque: 12-277 in-lb*

Shaft: 3/8"-1 1/8"

Diameter -

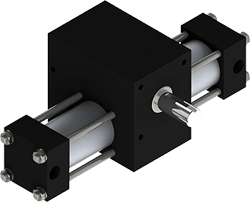

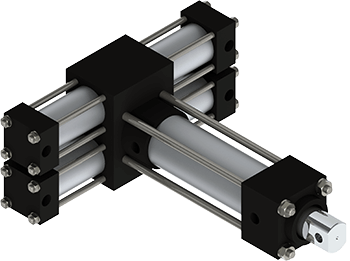

Indexing Indexing ActuatorsSingle RackX1*60psi

Indexing Indexing ActuatorsSingle RackX1*60psi Torque: 9 in-lb*

Torque: 9 in-lb*

Shaft: 3/8*

DiameterX2*60psi Torque: 29 in-lb*

Torque: 29 in-lb*

Shaft: 1/2"

DiameterX3*60psi Torque: 89 in-lb*

Torque: 89 in-lb*

Shaft: 3/4"

DiameterX4*60psi Torque: 208 in-lb*

Torque: 208 in-lb*

Shaft: 1"

Diameter -

Stepping

Stepping -

Multi-Motion

Multi-Motion -

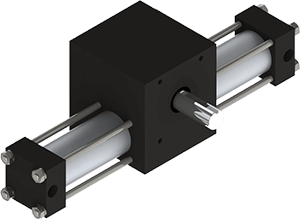

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi

Nitpicker Nitpicker ActuatorsSingle RackPX2*80psi Torque: 39 in-lb*

Torque: 39 in-lb*

Shaft: 1"

Diameter -

Shaft Mounting Adapters

Shaft Mounting Adapters

SPECIALIZED ACTUATORS TO OPTIMIZE YOUR PRODUCT

Rotomation’s standard product line is highly configurable and adaptable to a very broad range of applications, however, we also make custom solutions. Here is an example of one in which we were able to provide a special product optimized for a customer’s specific application, and by doing so, simplify their production, improve their product, and reduce their cost.

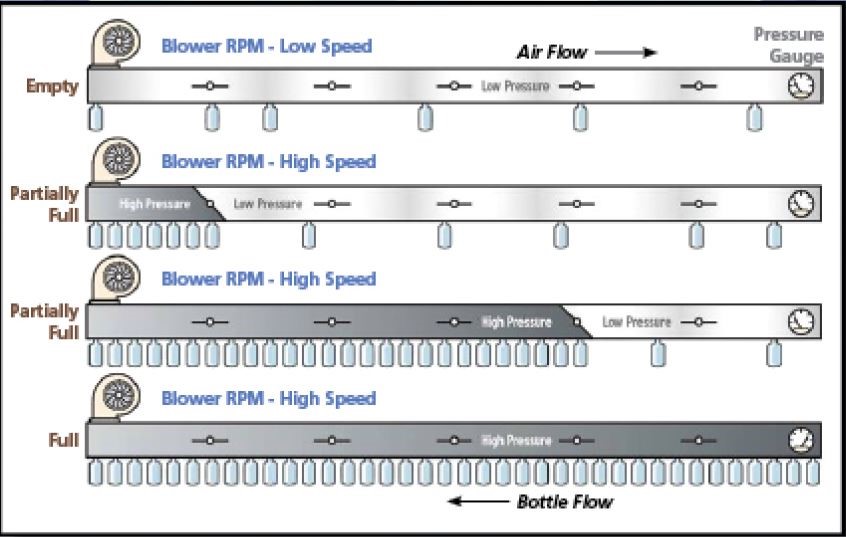

Advanced Manufacturing Technology (AMT) in Loveland, Colorado manufactures state-of-the-art conveying equipment for the bottling industry. One of their products, used for moving empty plastic bottles at high speed between the blow molder and the filling equipment, has a unique feature to precisely control drive pressure for each 10’ section of conveyor. Controlling drive pressure this way is key for a jam-free conveyance of today’s lightweight bottles. AMT conveyor plenums are segmented into high and low-pressure zones by means of dampers located at intervals down the length of the conveyor. As the conveyor fills with bottles the dampers adjust to provide higher pressure where bottles are accumulated and require more drive.

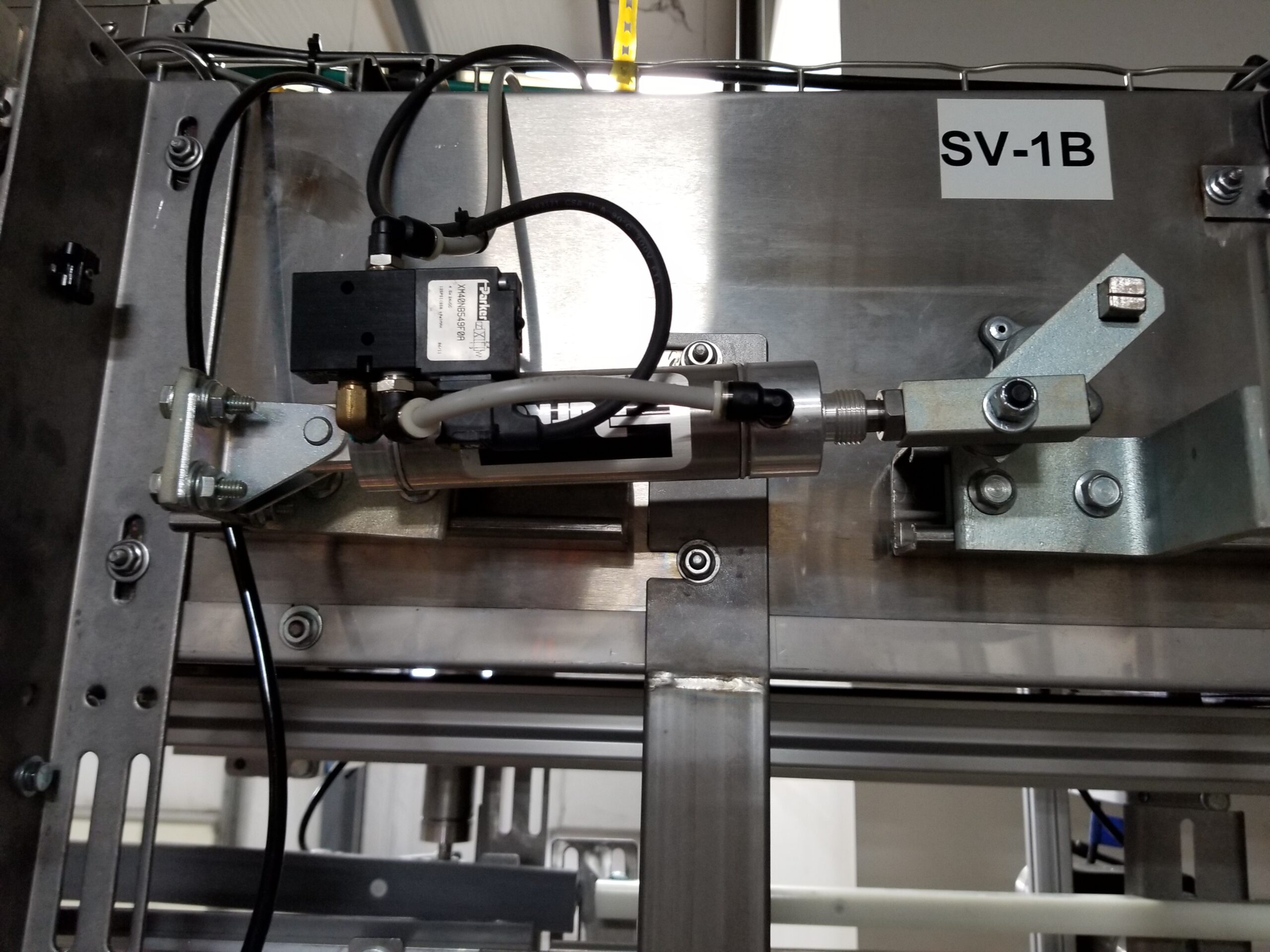

AMT’s original solution included an air cylinder driving a lever that was attached to the square damper shaft. Mounting brackets incorporated the adjustable stops needed to adjust the motion of the damper. A directional control valve and the related plumbing had to be installed. In some cases, the assembly had to be shielded to protect personnel from pinch points. The time required to assemble and adjust all of this was substantial.

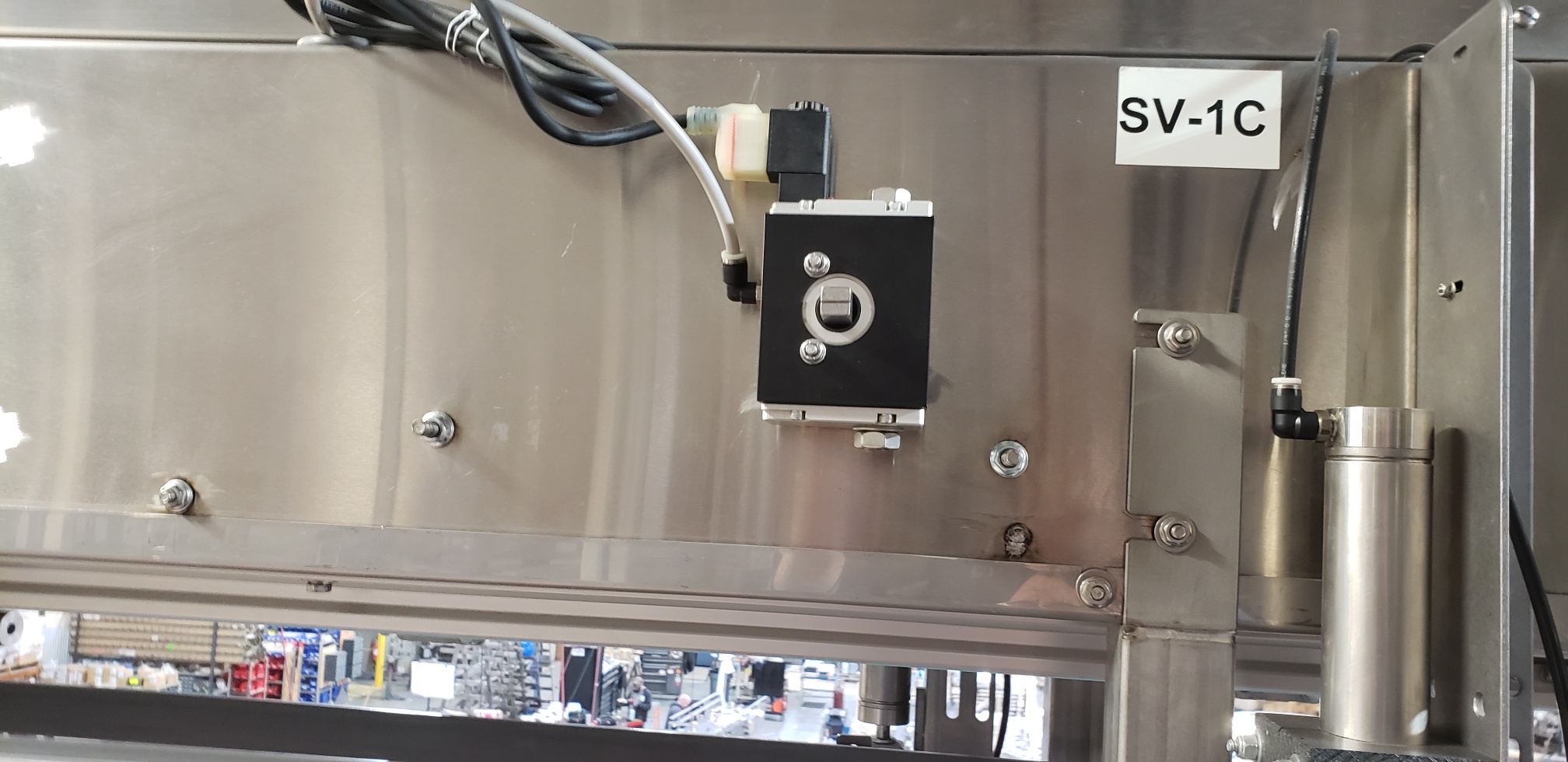

Rotomation’s solution was a rotary actuator designed just for this application. It has a square hole through the shaft which accepts the damper shaft and eliminates the need for one of the duct-mounted bearings. The directional control valve is built into the actuator, so only a single air line is needed. Fixed orifices control the speed, eliminating the need for adjustment at assembly and reduces problems in the field due to user error. The actuator has built-in rotation adjustments which are easy to set. Mounting is simple and quick, with just two bolts, the air line, and a special lighted cable for the valve. The actuator is protected from damage by washdown and has no pinch points.

Rotomation engineers and AMT engineers worked through a couple of iterations to perfect the product in a short timeline, and it is now used for all of AMT’s product of this type.

Call Rotomation today at 386-676-6377 to discuss your application! Our engineers are ready, willing, and able to provide a solution to help you optimize your design.