Dear Mr. Lane,

It is with great pleasure that I tell you, on behalf of the whole Nammo Space team, that the launch of our first hybrid sounding rocket was a complete success.

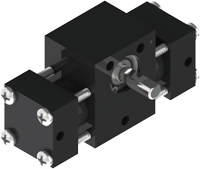

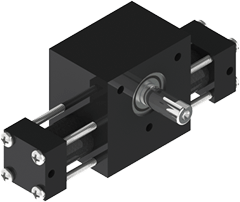

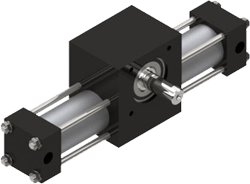

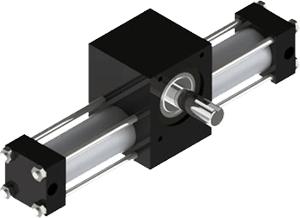

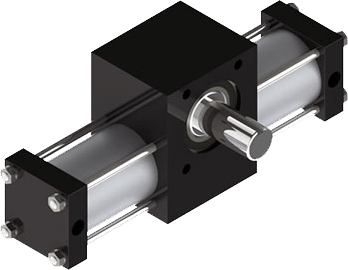

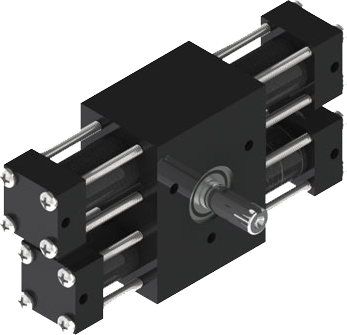

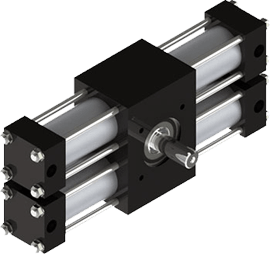

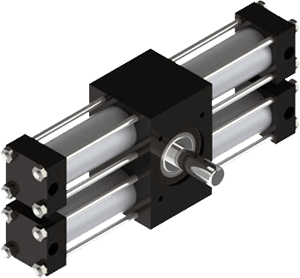

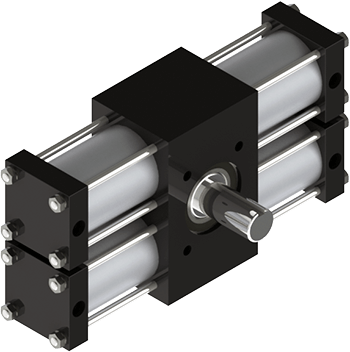

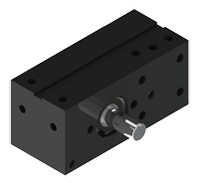

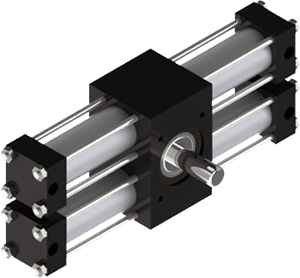

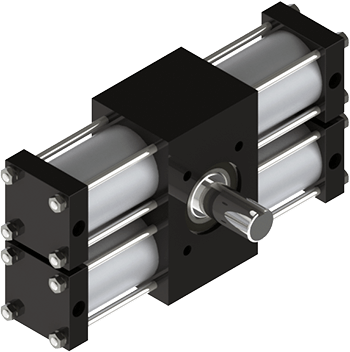

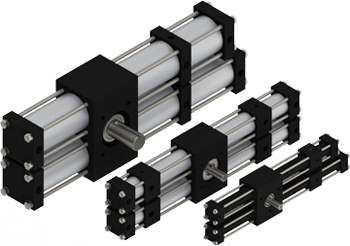

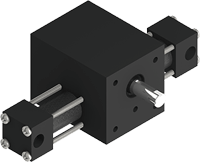

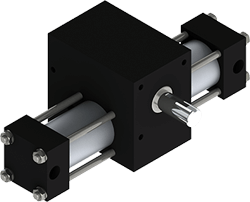

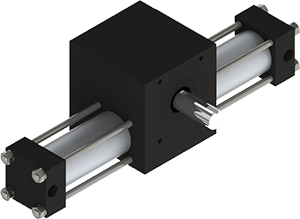

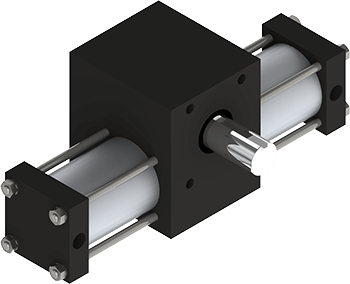

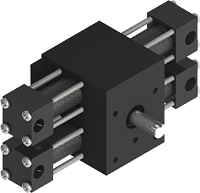

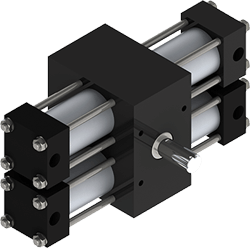

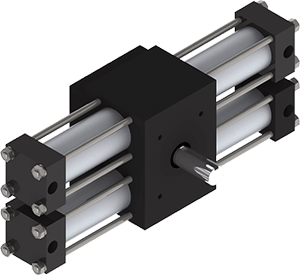

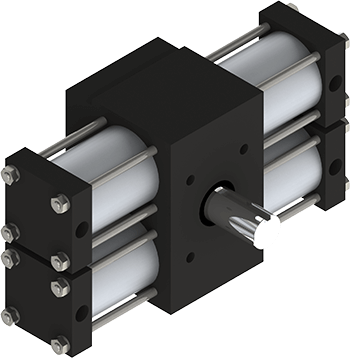

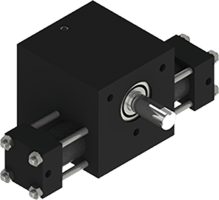

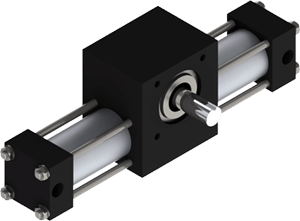

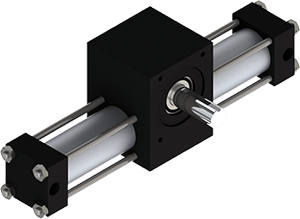

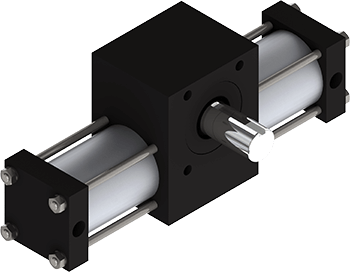

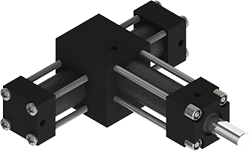

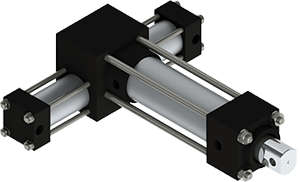

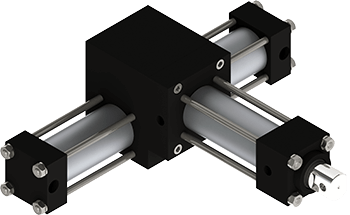

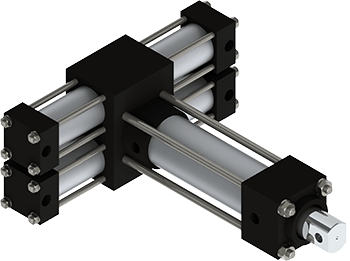

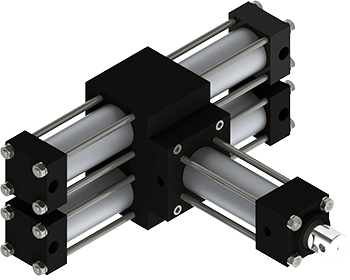

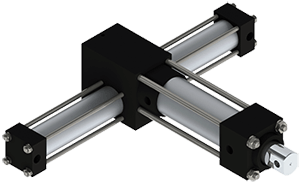

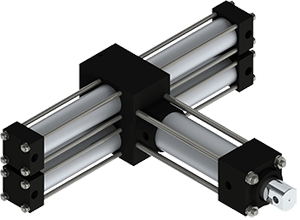

As part of the Ground Support Equipment for this launch (as well as during the static test campaign), the 3 positions actuators that we acquired from you were used to fill the propellant in the rocket and to pressurize the full system. Both actuators worked perfectly fine and we are very happy with their behaviour. You can find attached a picture of the installation of the A32 actuator on the launch pad with the rocket already in position.

Bastien Haemmerli

Development Engineer - Hybrid Rocket Propulsion

Aerospace Propulsion

Nammo Raufoss AS ![]()