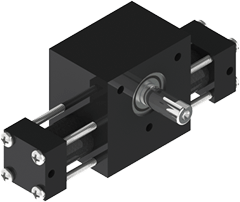

Holy cow! these people are rockstars! I have a Rotomation on our canning line.

So the canning manufacturer was the one who actually bought the equipment

from Rotomation but about a million cans and four years later I'm well out of

any warranties. Anyway, it started off I needed just a small part for repair on

the Rotomation. They overnighted it at no charge!

Then human error set in. I know I miss assembled something and could not

figure it out. Hours and hours of tech support on the phone and were

extremely patient, did a Team meeting for a few minutes, exchanged

photographs and diagrams. All in all, it was several hours of tech support

throughout the day today. Finally, they help me figure out my human error

and everything is working at should be they really went above and beyond

the call and I would have to say I highly would recommend them and their

equipment to anybody based on my experience!!!

Bob Southard, Burnt Hickory Brewery 7/15/21