Ensuring Longevity and Efficiency in Harsh Environments

In industrial machinery and automation, actuators are crucial for providing motion in automated equipment. However, these vital components frequently endure harsh conditions that can affect their performance and longevity. That is why it is crucial to implement protective measures. At Rotomation, we prioritize safeguarding the integrity and efficiency of your actuators. We offer a range of protective solutions tailored to your needs, guaranteeing smooth and dependable operations.

Washdown Protection for Enhanced Durability

Our washdown protection feature is tailor-made for the prevention of damage due to ingress of water or corrosive fluids. This protection is especially beneficial in industries where rigorous hygiene standards necessitate frequent cleaning with water or caustic solutions.

Unlike some other manufacturer’s products, Rotomation’s washdown protection features are fully integrated into the actuator, so no external dimensions are affected. Washdown protection is available as a standard option (does not affect delivery) on all 1” and larger bore rotary actuators, AL75, all indexers except X2, as well as multi-motion actuators PA2, PA22, and PA3. Others may be available on a special basis.

Washdown protection is often combined with fluoroelastomer (FKM) seals if the environment includes chemicals that attack our standard nitrile. When this option is specified, all the seals in the actuator will be FKM except shaft seals which are PTFE.

Rotary actuators with the washdown option are equipped with stainless steel pinion shafts and hardware for corrosion resistance. Washdown indexer shafts are nickel plated, retaining the very high hardness required by the internal clutch bearings.

Washdown option used for cleanroom or other high purity environments

The washdown option also lends itself to use in applications where the normal breathing of the actuator, which is lubricated internally with grease, could contaminate a high purity location such as a clean room. With this option, the actuator is completely sealed, and there is a vent port in the body. This port can be plumbed to a central exhaust or other location, to allow breathing without contaminating the controlled area.

Alternative materials or surface treatments

Rotomation’s standard anodized aluminum bodies and end caps are resistant to moderate environments but may be degraded by certain materials. Two alternatives that are offered on a special basis include hardcoat anodize and electroless nickel. Depending on the chemicals, these may provide a cost-effective solution.

Stainless Steel Actuators: The Pinnacle of Chemical Resistance

In scenarios where exposure to corrosive materials is a concern, Rotomation can produce any of its products with all external parts made of stainless steel. The washdown option is normally included, to prevent caustic materials from getting inside.

Because these actuators are built only on a special basis, the customer can specify which stainless steel alloy they prefer. 303/304 is a lower cost option due to its high machinability and lower cost, but if 316 is required for especially harsh environments, that can be specified.

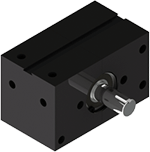

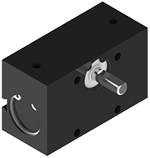

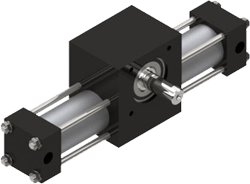

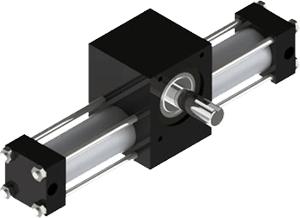

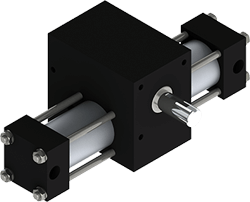

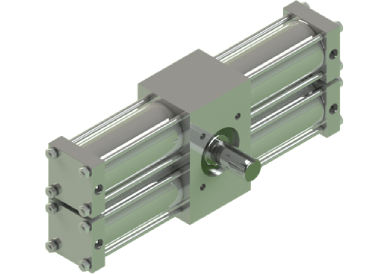

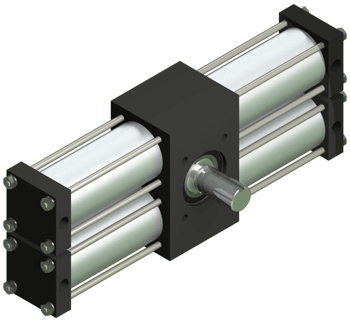

(Left Image) Special stainless steel A42 rotary actuator (Right Image) Standard A42 rotary actuator with aluminum parts.

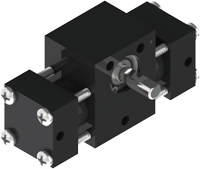

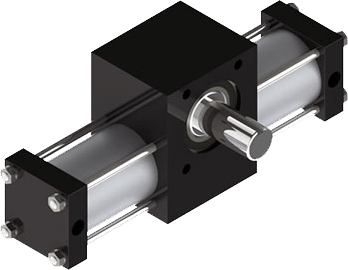

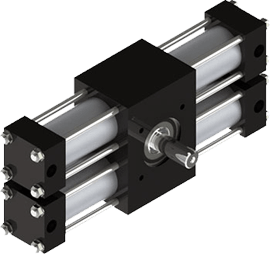

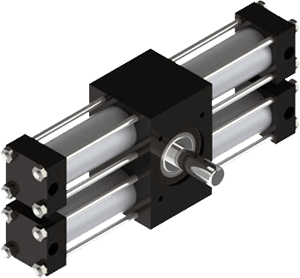

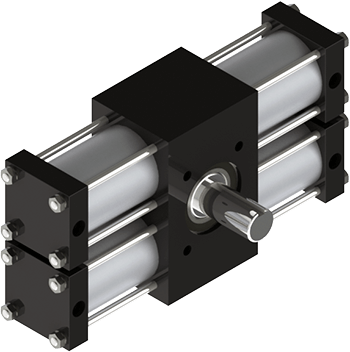

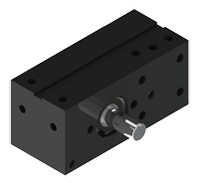

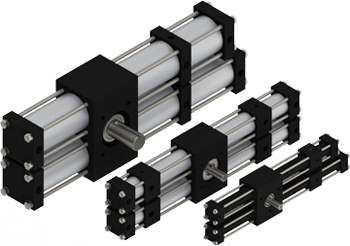

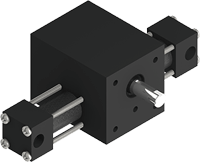

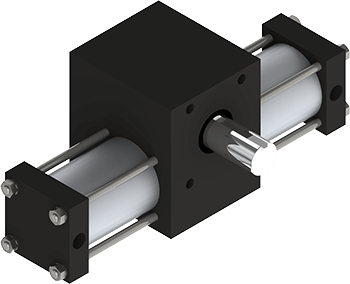

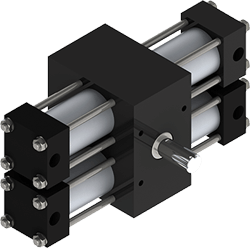

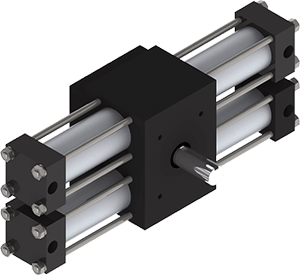

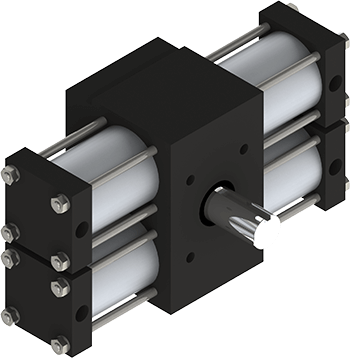

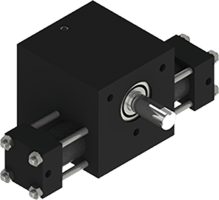

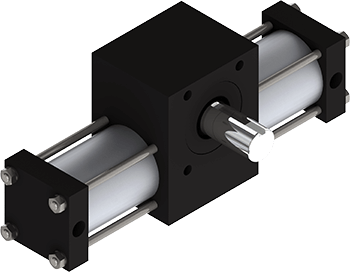

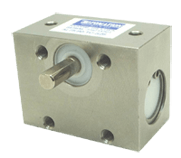

The very compact AL 75, with its inherent soft start and stop.

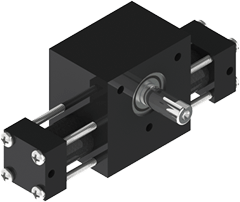

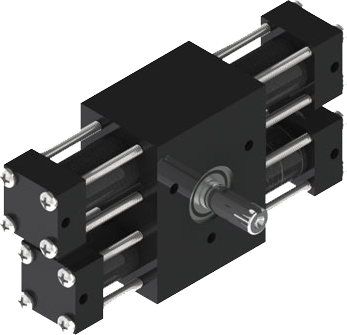

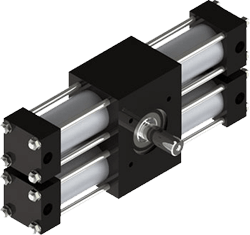

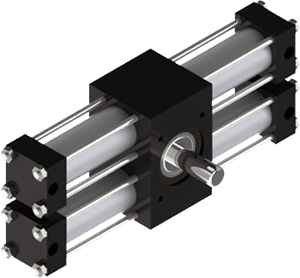

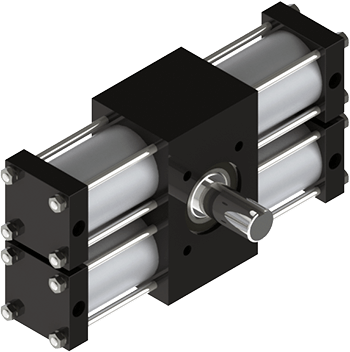

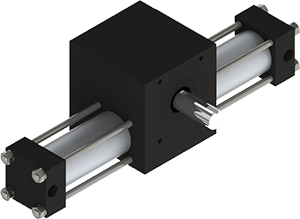

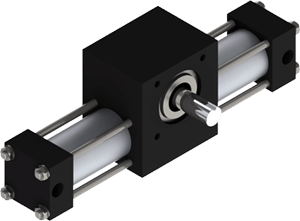

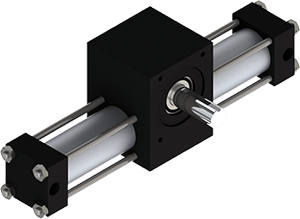

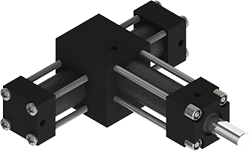

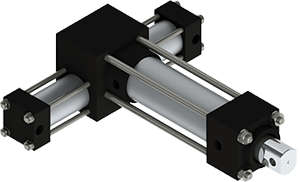

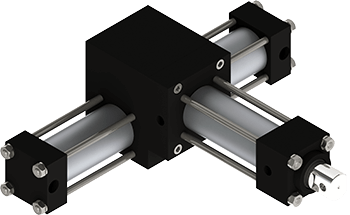

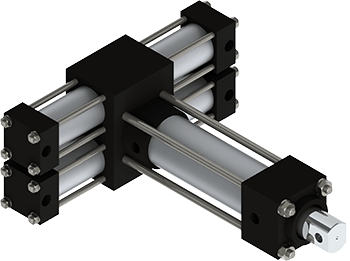

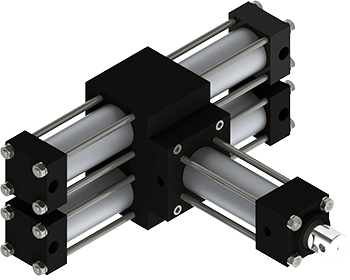

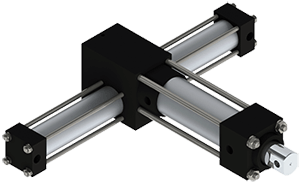

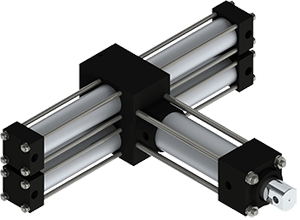

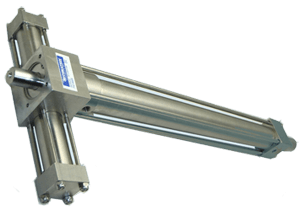

A long-stroke PA2.

Tailor-Made Solutions for Unmatched Flexibility

Rotomation stands at the forefront of innovation in rotary actuator technology, underscoring our commitment to providing solutions that precisely fit your unique requirements. We understand that one-size-fits-all solutions rarely meet the nuanced needs of specialized applications. Therefore, we offer flexibility, allowing you to configure your actuator to align perfectly with your operational demands.

Whether it is a simple modification to the shaft size, projection, or machined features such as keyways, flats, through holes, etc., or more complex customizations like opting for alternative materials for the main body and end caps, Rotomation is equipped to enhance your product and reduce costs. Our understanding of the critical nature of actuator performance in your operations drives our dedication to crafting solutions that not only meet but exceed your expectations.

Connect with Us for Personalized Consultations

Interested in exploring the full potential of our actuator protection options? Rotomation is here to assist. We invite you to contact our team for more information or to request a quote.

Contact Us for More Information!