What's Unique About Us?

Rotomation manufactures high speed, heavy duty pneumatic actuators that produce several shaft motions. All products are extremely configurable, which separate us from our competitors and give users maximum flexibility in their design. Another unique advantage we have is our ability of supplying special actuators quickly and at a reasonable price.

Unique Products

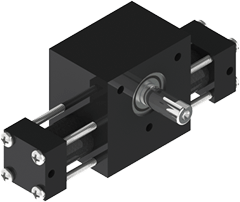

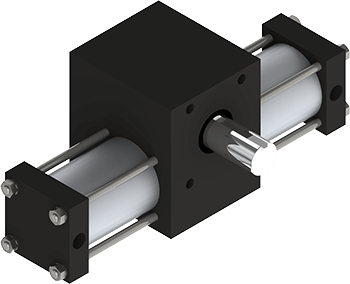

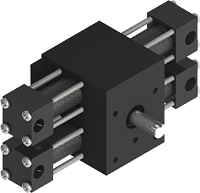

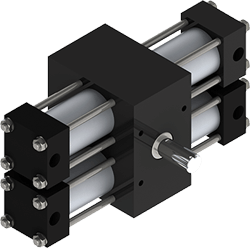

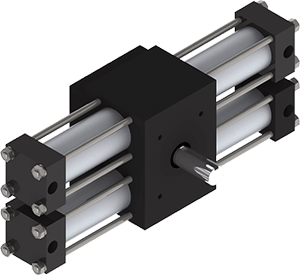

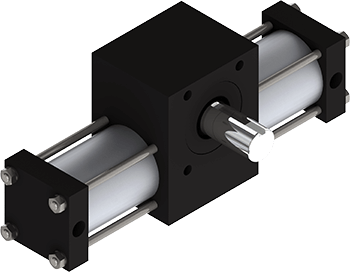

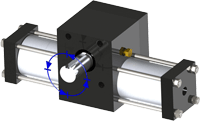

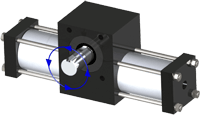

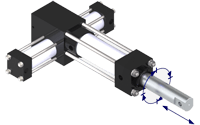

Like all of our competitors, we have a basic line of bidirectional actuators that rotate between two positions. Like some of our competitors, we also carry a line of multi-position actuators that rotate between three, four, or five positions in any sequence and a line of multi-motion actuators that combine linear stroke with rotary motion, independently-controlled but all in one actuator. But here are a few aspects that set us apart from our competitors.

We offer a line of unidirectional actuators that rotate in increments and prevent backward rotation. These actuators are divided in two main families, stepping and indexing.

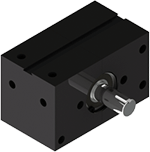

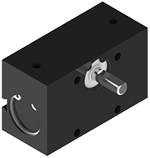

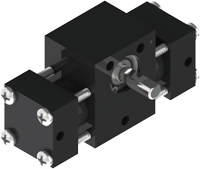

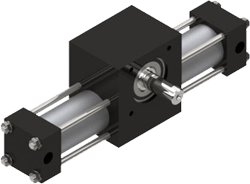

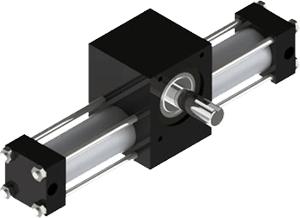

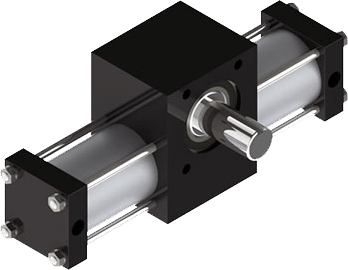

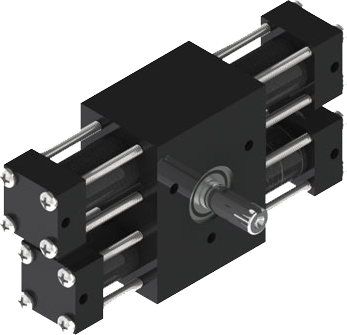

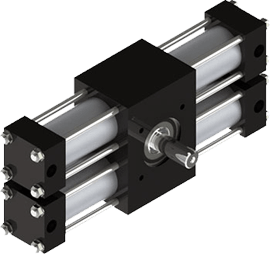

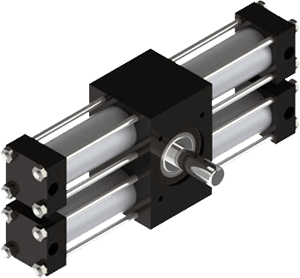

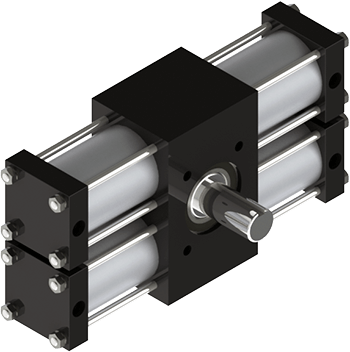

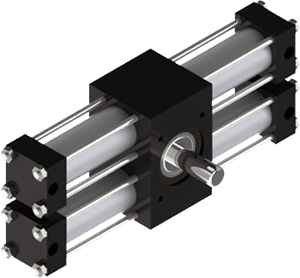

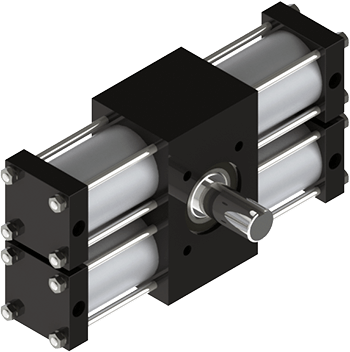

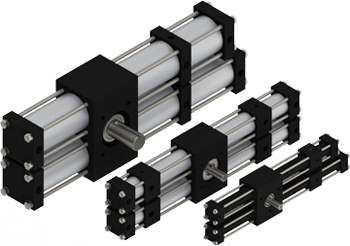

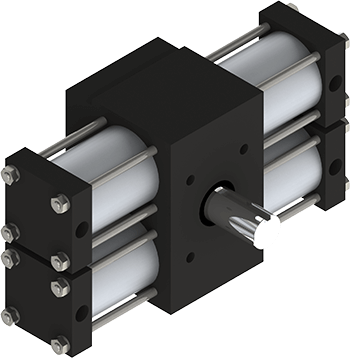

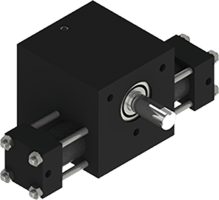

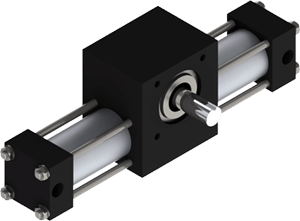

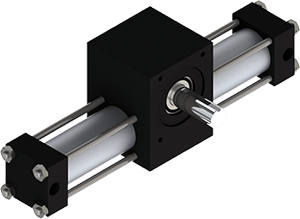

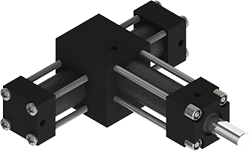

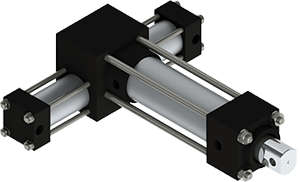

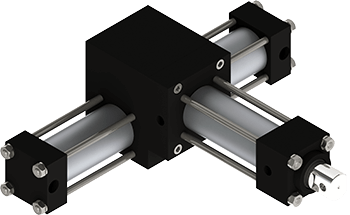

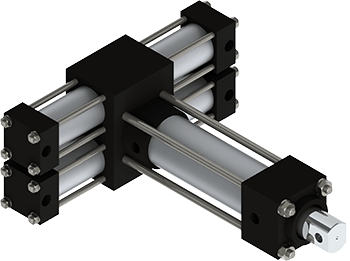

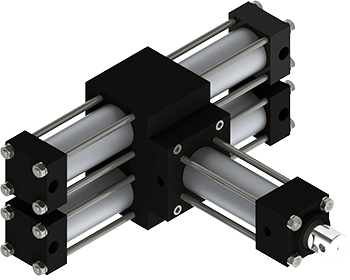

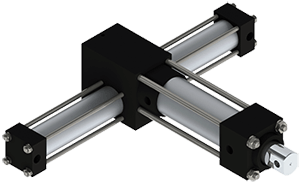

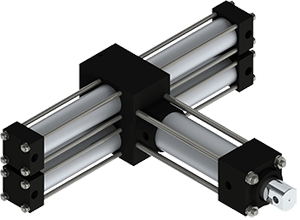

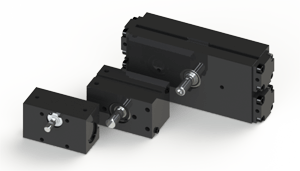

Our family of compact actuators include a variety of rotary actuators such as our A032, that provide more torque and bearing capacity than any other actuator of similar size on the market, our AL75 with its characteristic slow start/stop motion inherited from its patented drive mechanism that is unlike any other rotary actuator we offer. Image below shows a group shot of our three compact rotary actuators.

Unique Quality

All our actuators are manufactured with the highest degree of quality, surpassing the industry standard. Our pneumatic actuators are therefore capable of high speed cycle rates and feature an inherent heavy duty construction, only matched by hydraulic actuators. Our actuators are used in harsh environments such as in metal working applications, electronic and mechanical assembly applications, demanding testing applications, food packaging applications, and semi-automated bakery production lines, among others. Our actuators are so reliable and durable that they are very popular among the automotive, semiconductor, food, and pharmaceutical industries.

We use nothing but the best and highest quality materials available in our product lines and always design for maximum ruggedness, reliability and durability. Materials such as 2024 aluminum and 4150 heat-treated steel are commonly used in the manufacturing of our parts and we use the latest and greatest coatings and treatments to ensure maximum endurance. We also offer alternate materials to accommodate specialty applications requiring enhanced corrosion resistance and/or clean environments.

Unique Application

Whether your application requires a unique feature on a standard unit or a completely new actuator, we have a solution for your unique application. About 40% of the actuators we produce require some special feature or modification, or in some cases, they are completely new products, depending in the application and the customer's request. Click to see examples of our latest customized and/or custom-made actuators.

Unique Satisfaction

Our attention to detail and unique team of knowledgeable technicians and professionals stand behind the quality of our products to ensure your satisfaction and reliable performance for millions of duty cycles and years to come. Furthermore, our excellent sales and engineering team will guide you through the process of selecting and specifying your actuator to satisfy your specific needs, to help you meet and exceed your production expectations and be there for you if you need any kind of support along the way.

Here at Rotomation, Inc., you get targeted engineering services, personalized customer service and unique technical support, all included in the price of the actuator. So when you choose our products, you get our expertise; it's that simple!